Hi All , just some photos of a job I have just been doing , a friend needed some PVC collars making that fit on a driven shaft to mix paint or some type of job like that. Anyway he gave me one to copy and this is what it involved. There is probably lots of ways it could have been done other than this but it is partly working around what gear is able to be reached and what gear is actually working and not needing fixed lol.

Its 100mm solid PVC bar , so first job is to cut into decent sized bits for the lathe, I did this on the big bandsaw.

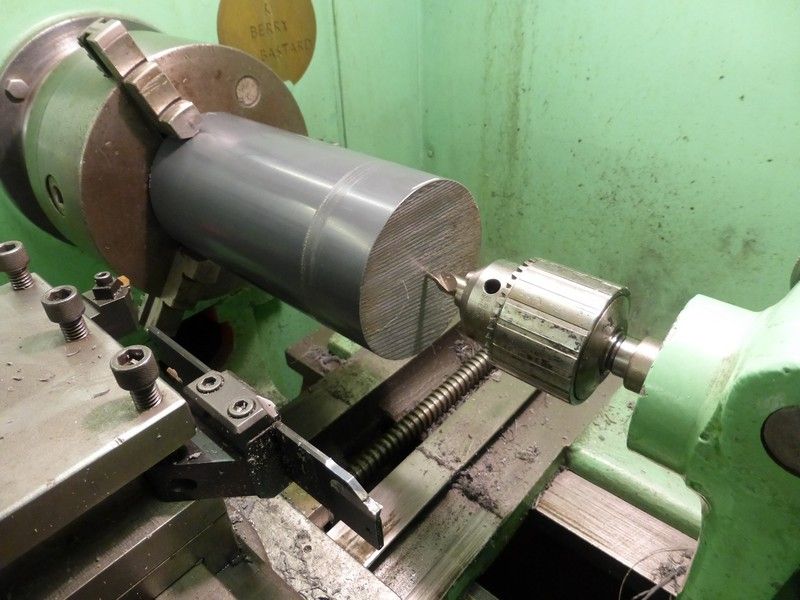

Then mounted this bit into the Binns and Berry lathe, center drilled the end, supported with revolving centre, and skimmed the outer surface until true and round. Its extruded bar so not that perfect to start with. I then draw the tool along the length so it has a scribed center height line for use later.

It was then drilled out with large drill a couple of mm under the final bore size, makes plenty shavings !

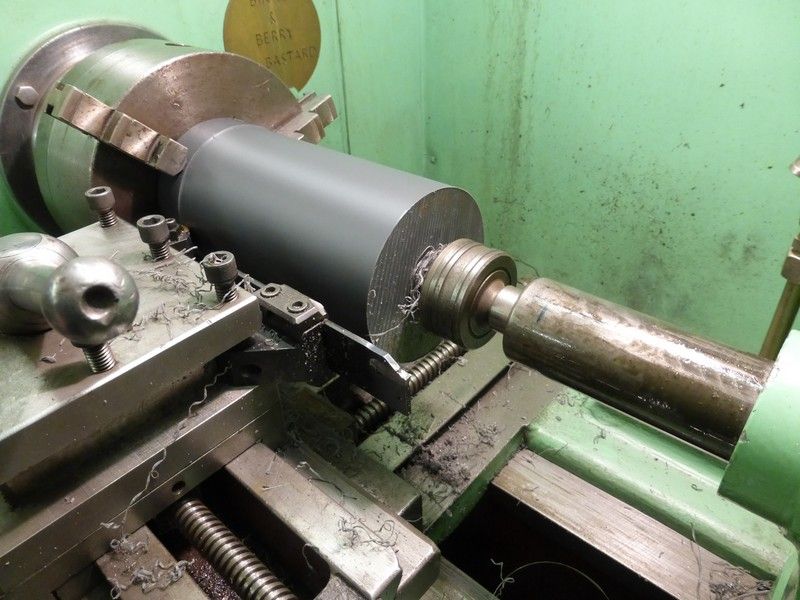

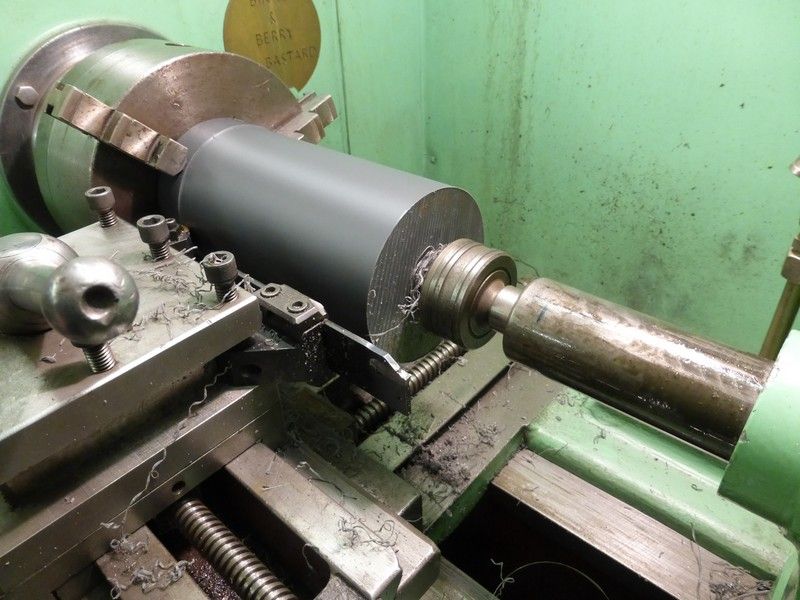

Next stage is to part off slightly too long as the parting tool leaves rough finish on both the part and the bar left in the chuck, so each part needs skimmed to size which will leave decent finish too.

I then did one test bore to get the right size for the sample shaft to fit then do each collar without touching the setting for the boring bar so they al match, then do the same with them all length wise too, by doing one , leaving the tool setting, then doing the rest without moving the settings.

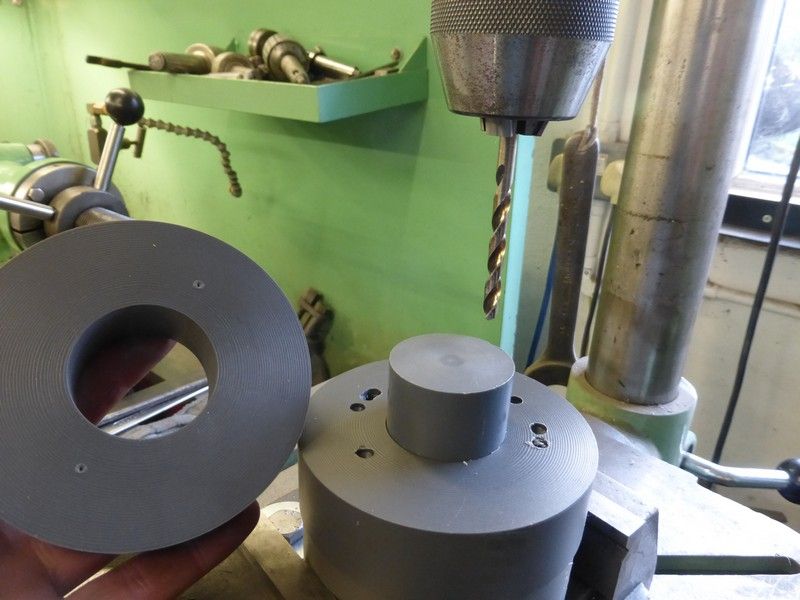

Next there are two 6mm holes drilled through from flat side to flat side, these are 90 degrees out from a 8.5mm hole that goes straight through the collar from one side to the opther. I used the original sample collar to center punch through to mark the two spots by using a section of shaft mouted into a base plate as a jig also lining it up with the center line that was scribed when still on the lathe. The same jig is then used then used to set up on the drill press to drill the holes. The collar can be rotated around the shaft in the jig so the holes are both same radius from centre point, then drilled in line with dotted marks.

Next its the straight through hole of 8.5mm , I have experimented before with this and drilling straight through seems to wonder off so I go from each side into the center using a jig type set up on the bridgeport. First the angle plate is set so it puts the drill center line on the collar, then the V block and stop black make the collar locate, the scribed center line is then lined up with the line scribed on the angle plate at tool center line and each collar clamped and drilled.

Then to do the matching hole on the other side I set a plastic 8.5mm pin in a scrap bit of alloy and located it the set distance from the angle plate and again on the center line scribed to the drill center. using the hole already drilled , this locates over the plastic peg, the collar clamped then drilled, as I did them just tested with a pin that reached right through the collar.

Thats it job done, I know things could have been done more precise with rotary tables etc but these are just rough and ready items to attach discs that spin in paint to so , if they do the job , its mission accumplished.

Cheers Mick.