Hello to all,

Hope everybody had a nice Christmas and Santa was very generous.

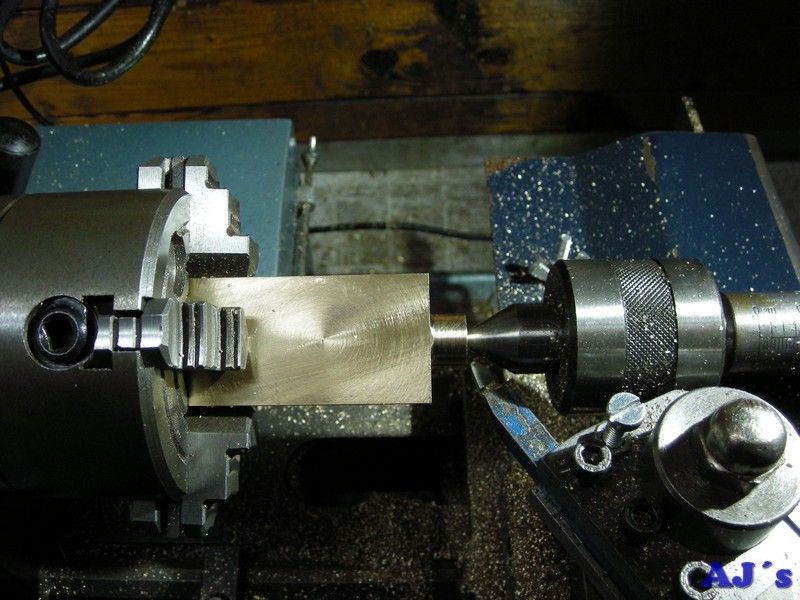

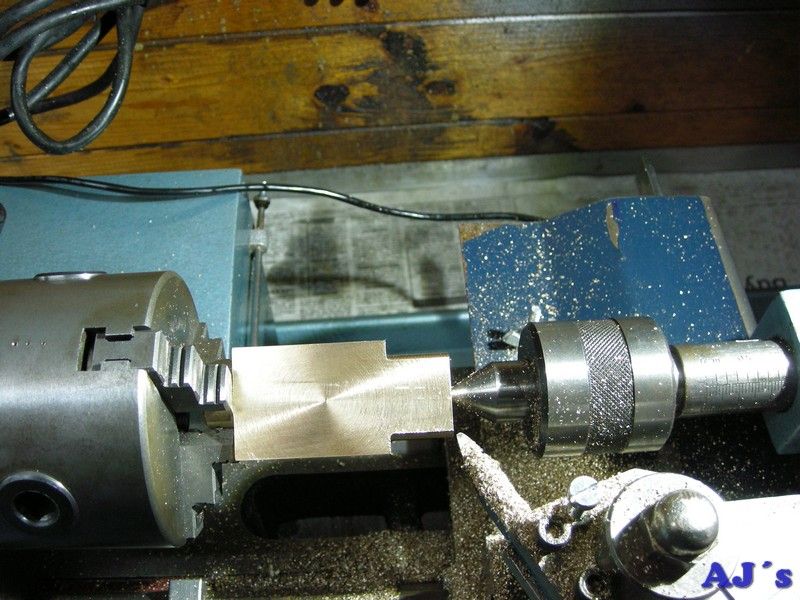

Next up was the valve chest and, as the mill is still out of commission, a piece of brass was fly cut to size.

It was then centered lengthwise,

and the boss for the packing seal turned.

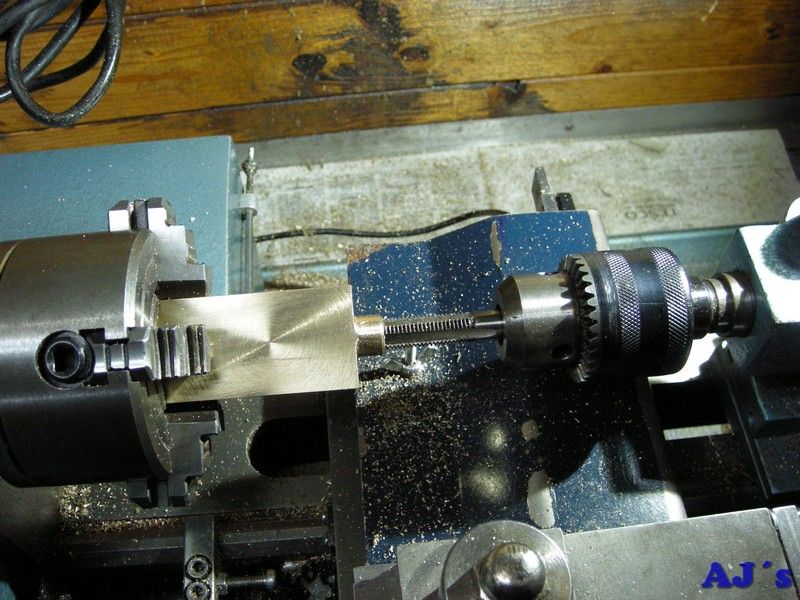

It was drilled and taped.

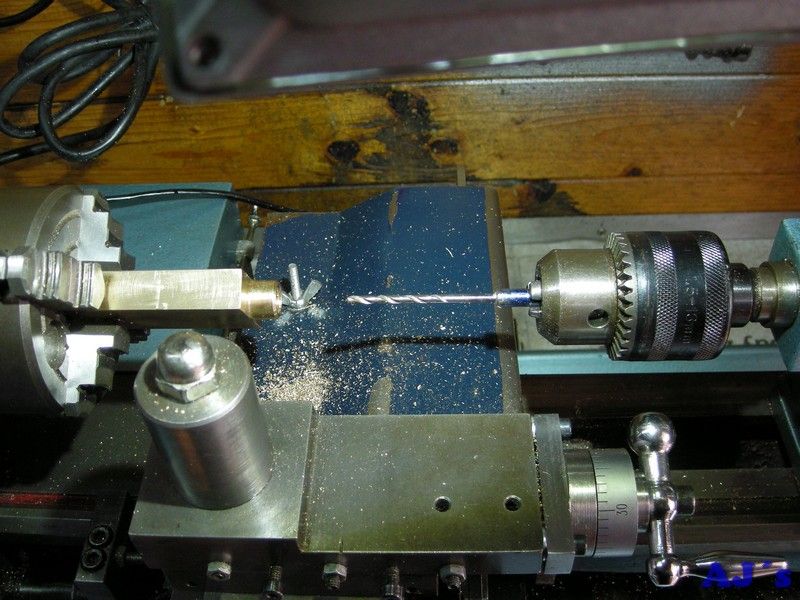

For the deep hole I had to make a long drill by soldering a drill bit into a length of bar.

Test fitting the packing nut and valve pushrod.

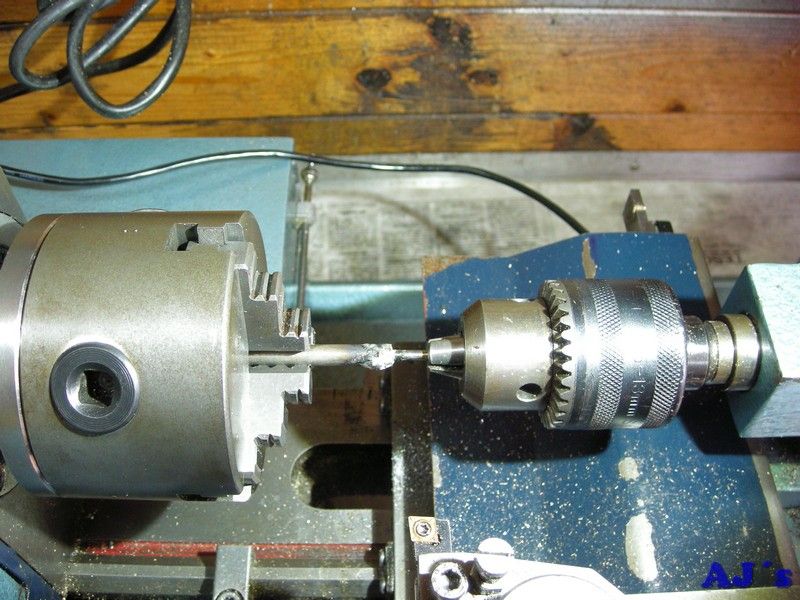

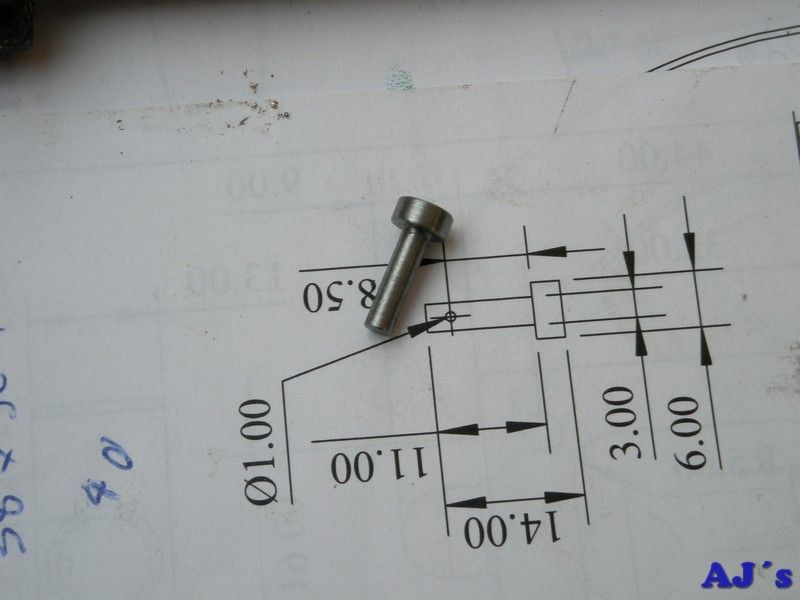

The part was then turned around and the boss on the blind side turned,

and parted off.

The round over was done by file.

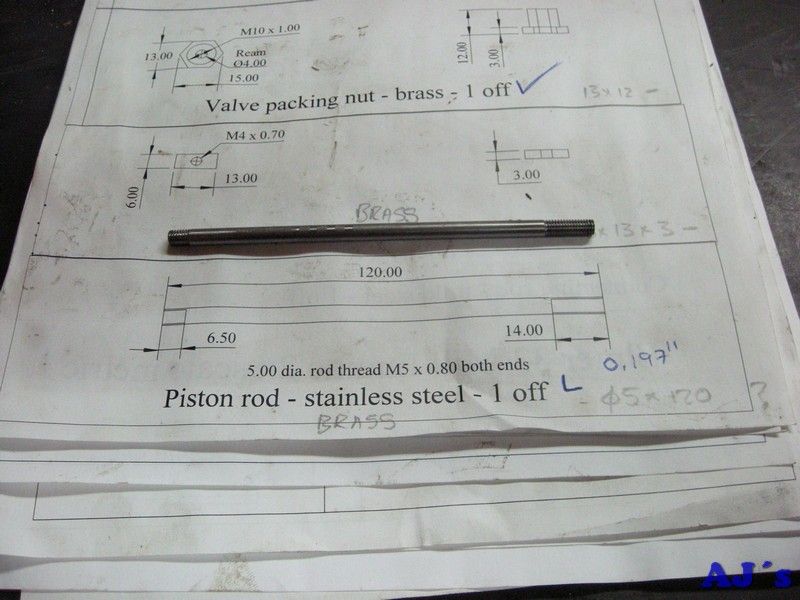

The piston pushrod was cut to length and threaded.

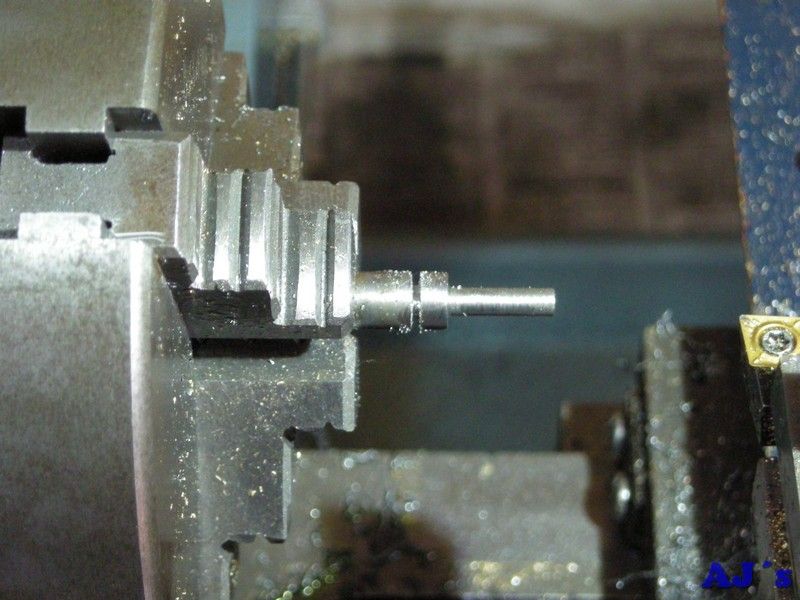

Tuning the pin for the valve pushrod.

Cheers

Abraham