Hi Lads , I have made a couple more small ' gadgets ' to make life easier when doing jobs on the lathe, again not my ideas, this is just the way I have done it but might give some others tips on how it can be done anyway.

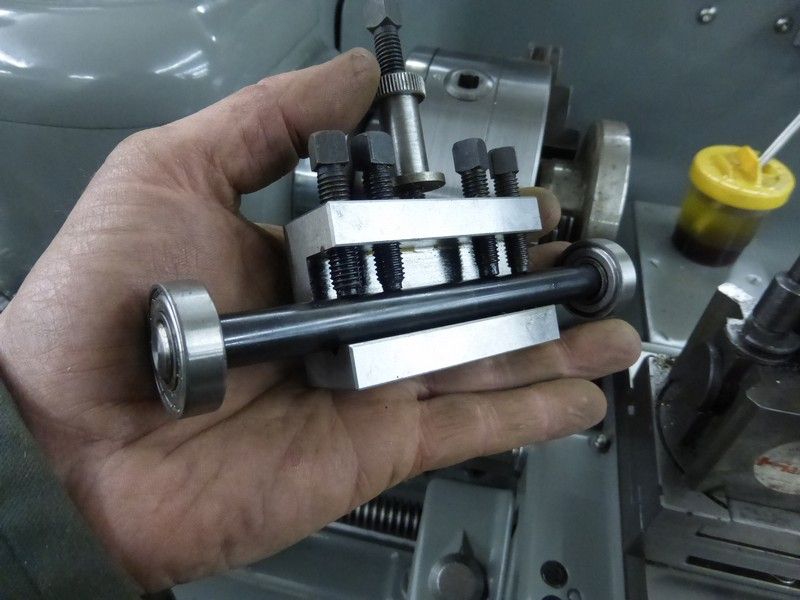

The first item is a plain rod with a bearing locktighted on each end again mounted into a quick change tool holder so its nice and easy to use.

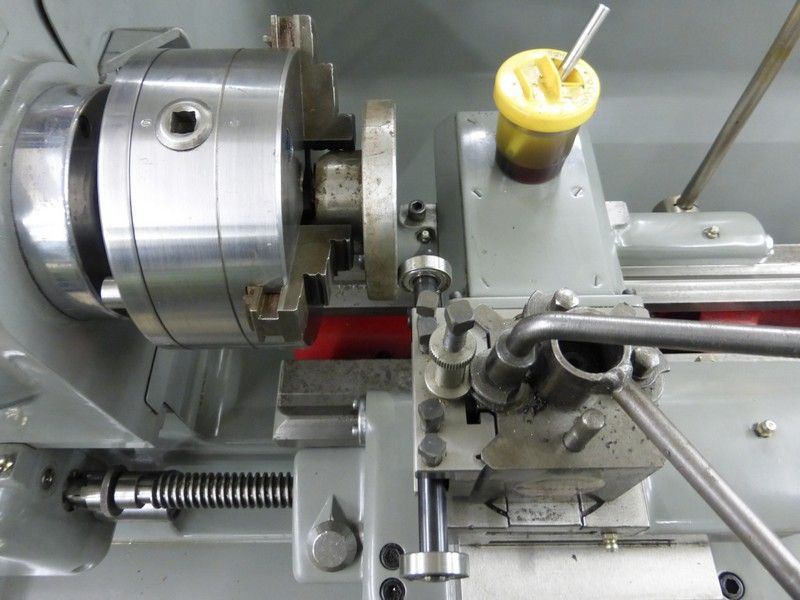

It can be used to true up a disc type object as shown here or maybe a flat disc inside the chuck jaws just nip the job in the chuck lightly then with the job rotating just lightly contact the bearing against the surface of the job until it runs true, then tighten up or if its something precise use the DTI to fine tune, just the bearing gets things pretty close anyway.

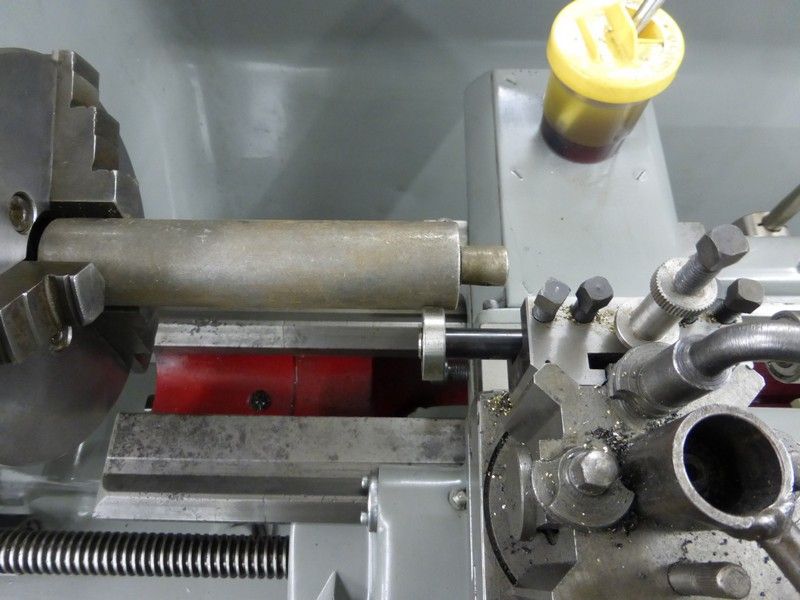

With it having a bearing on both ends the toolholder can be switched around and the other bearing used to true up a bar in the chuck as shown here.

Again a really easy thing to make but very useful, any size bar that will not flex too much and any size bearing will do the job really too.

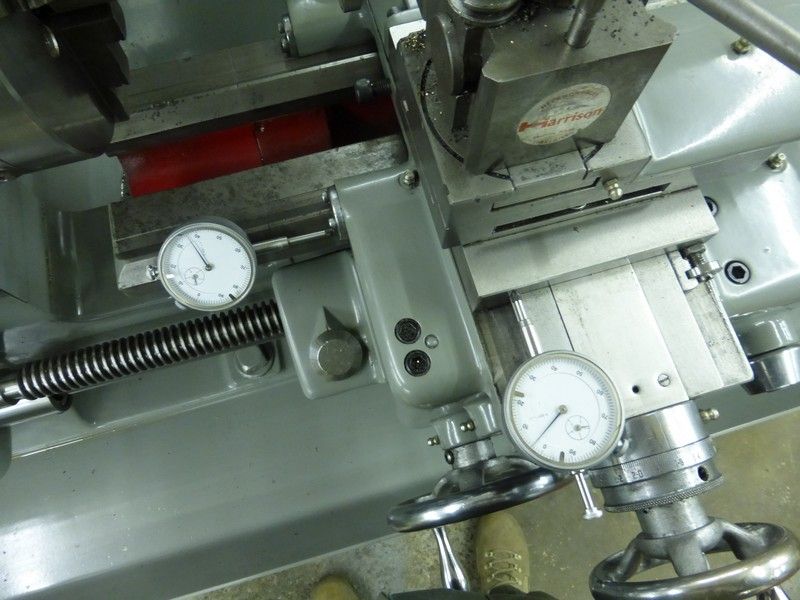

The other 'gadget ' is a DTI with a magnet stuck to the back so it can be used on the lathe bed, or any other surface on milling machine , drill press etc where it might be handy.

I had two matching Batty DTI's that I picked up cheap but with plain flat backs , the backs were made of plastic and when I held a magnet to the back it was binding up the spring return of the DTI. I cut a thin steel sheet into a circle and put this between the magnet and the back of the DTI which solved the problem. I used some strong magnets off Ebay 25mm round and 2mm think.

I used two part epoxy glue to stick the steel backing plates to the DTI's then a dab more to go between the magnet and the steel, works a treat and strong enough for the gauges not to move in use.

My lathe is metric micrometer collars so having the two imperial DTI's is handy if I want to use imperial, you could do this the other way around with Metric DTI's on imperial lathe too.

This is where they live when not being used, the back of the cabinet door, they just stick to any steel surface so nice and handy.

Cheers Mick.