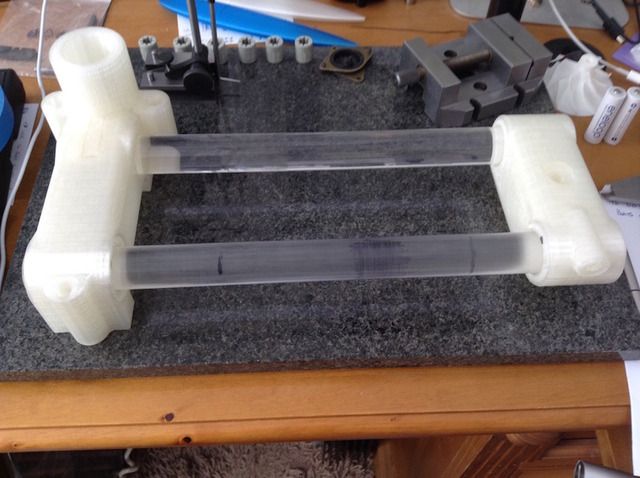

Ahhh, its only taken about 6 months to get back to this project. Work has slowed a bit and I got some workshop time for my own stuff. Last time I had been thinking about making a reamer for the 3D prints in order to get the front bar inserted. That idea got turned on its head, and I decided to machine the bar.

At this point I wished I had picked up a travelling steady for the Myford whilst I was at the Doncaster show. I made a superb elongated lobed barrel...

Good job this is my time... Out with the wet and dry, using 3in1 oil as lube, I have many hours of fun polishing it to size. All is not lost, as my 3D print bores are also elliptical so the bar fits in two places.

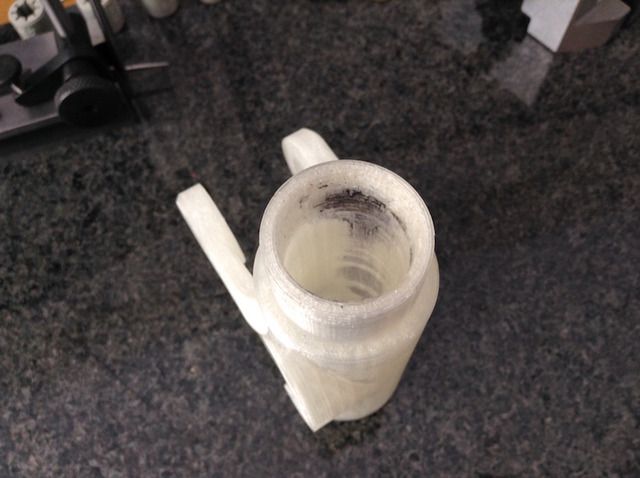

I used Sharpie on the bar to transfer the high spots. I can now scrape the internal bore of the print to better match the bar, old technique modern materials. Why aren't I machining these ? Well, they are hard to hold and flexible, tools can too easily dig in. It would have been better to design the part fit better from the start

Now where's the fun in that...

The bar fits and is a loose in the ends. I can overcome this to some degree when I print the dust shields that fit on the prints and they can be classed as consumable items.

I'm pleased with how it's going the parts so far take only a few days to print. Corrections and modifications to drawings are quick and easy depending what materials you have on hand.

The scraping tools work great by the way, just a tad more aggressive, so work gently.