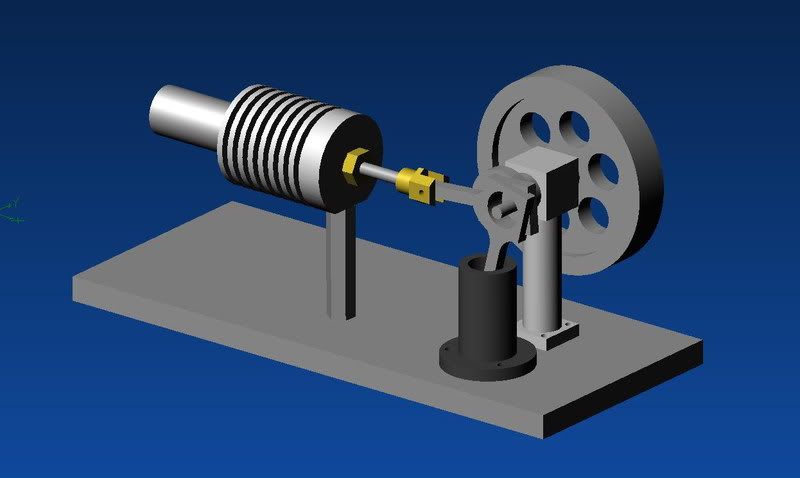

It was January 2008 before I got back out into the garage again, but I had been studying stirling engines on the internet for the best part of a year. First I got a hold on the theory, then set about working out a simple configuration, again using bits of off cuts I have in the garage. Since it had worked fairly well on the oscillating engine, I used the 3D CAD to aid the design again...

I chose this configuration so that I would only need 1 crank, identical con rods and I thought i'd be cunning and hide the transfer passage under the base!

At first, I couldn't get the engine to work, depite thinking I knew the theory, for some reason, I hadn't followed some of the design rules I knew I should! The ratio of swept volumes was much too small, I'd got carried away trying to use what I had and forgotten what parameters were needed to make the thing run!

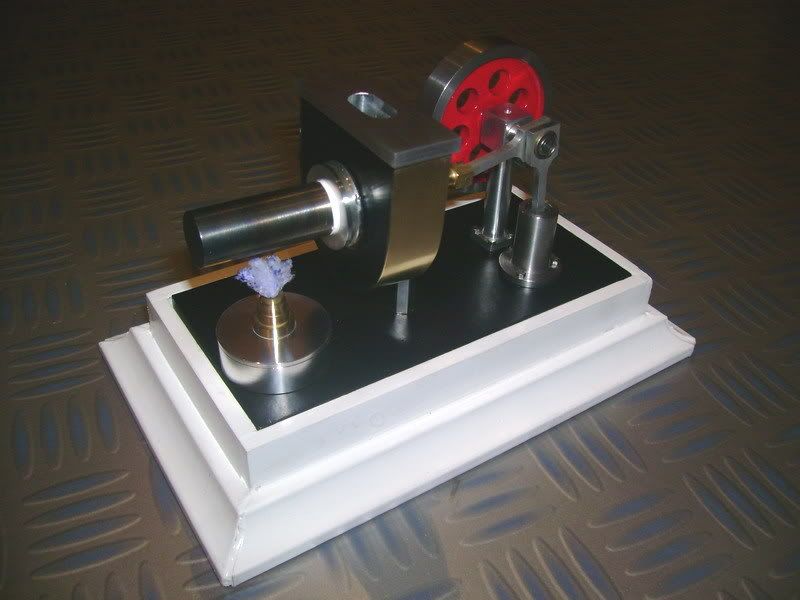

So I modified the design slightly, doubling the ratio of swept volumes between displacement cylinder and power cylinder. Now the engine was trying to work, it would run with ice cubes on the displacer cylinder, so I assumed my problem was insufficient cooling and promptly built a water jacket that hadn't been planned for ... this proved difficult as the displacer cylinder was aluminium, it was a bodge, because the jacket had to be araldited in place, but it turned out alright. When testing with the water jacket however, the engine would not run, and after a bit of dialogue with Jan Ridders, it became apparant that the problem was only partly down to cooling, but the main issue was leakage. Jan said forget about cooling, take it out of the equation, if the engine is ever going to run, it should run from time zero. I.e. when the flame is first applied will pretty much be its best chance. That sounds obvious now, and when submerging the displacer assembly in water and pressurising (with a tube and my lungs) a big leak around the hot cap interface was revealed. This was sealed up with PTFE tape and instantly the engine felt different, I could feel a little springiness when turning the flywheel over!

http://smg.photobucket.com/albums/v287/NickG24/My%20Stirling%20Engine/?action=view¤t=2008-07-2823-26-24_0008.jpg

This now looked promising and to my delight, the engine would now run for about 8 mins on the tiny spirit burner when the water jacket was filled with cold water. And the limiting factor was the amount of fuel it could hold, not the lack of cooling. At this stage I was using an old nylon shoelace as a wick, when I got some proper cotton wick, the performance improved 3 fold, it had previously run very slowly, now it was flying over! This all makes me wonder whether the water jacket was necessary now, I have not tried it without though!

This engine was again mainly built using my old machines, and some machines at our club workshop. However, when I got my new lathe, I took a finishing cut off everything with the new one which improved the surface finish and looks dramatically!

I was very pleased with this project, although I didn't finish it until August 2008 when I was on Paternity leave after my wife having our second son! It was a massive step up from doing oscillating engines and very satisfying to get the engine to run, and run well. It also taught me many new techniques that I hadn't previously used, such as screw cutting, the crank shaft / disc / pin was turned from 1 solid piece, as well as many milling operations.

Nick