Got to work on the lubricator assembly....

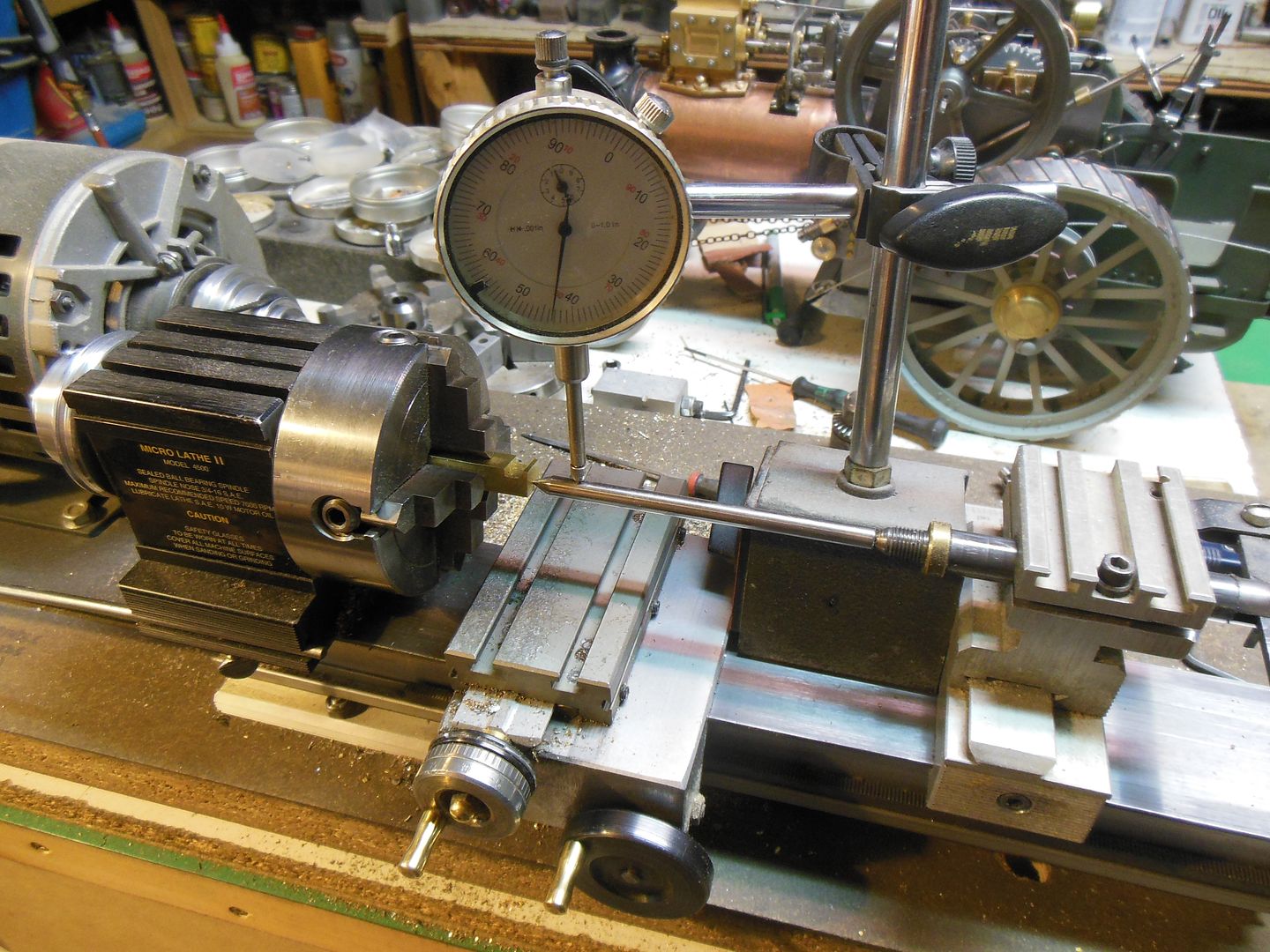

some milling, then set up in the lathe to drill and ream the bore of the cylinder:

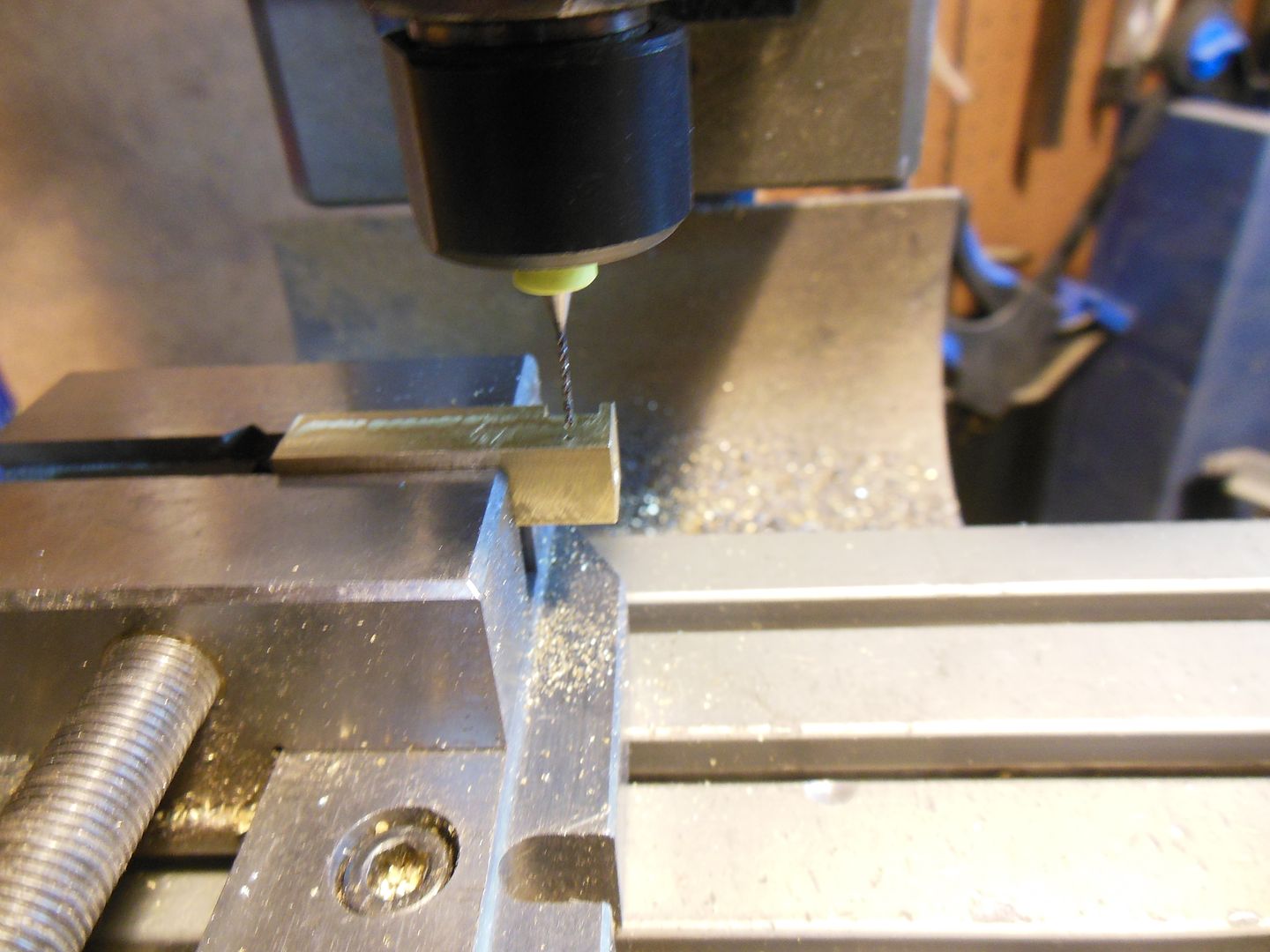

Then back in the mill to drill two No 65 holes as oil ports

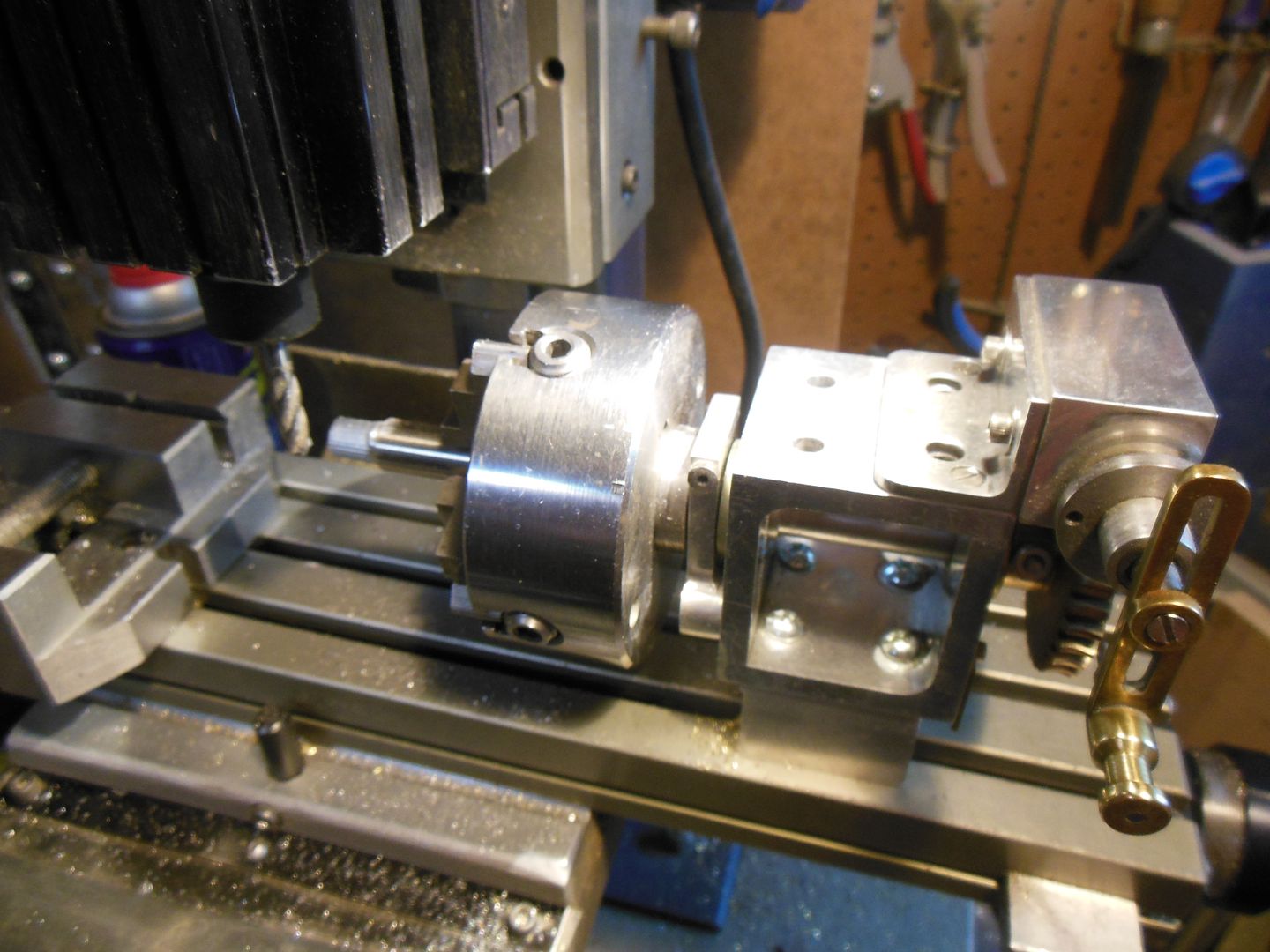

parted that off, and then turned some o-1 drill rod (silver steel) to size, and into the the dividing head to cut the ratchet wheel

parted that off and and hardened it, then milled up a bit of spare ali as a former for the brass tank parts

cleaned up, well fluxed, wired into place, and silver soldered

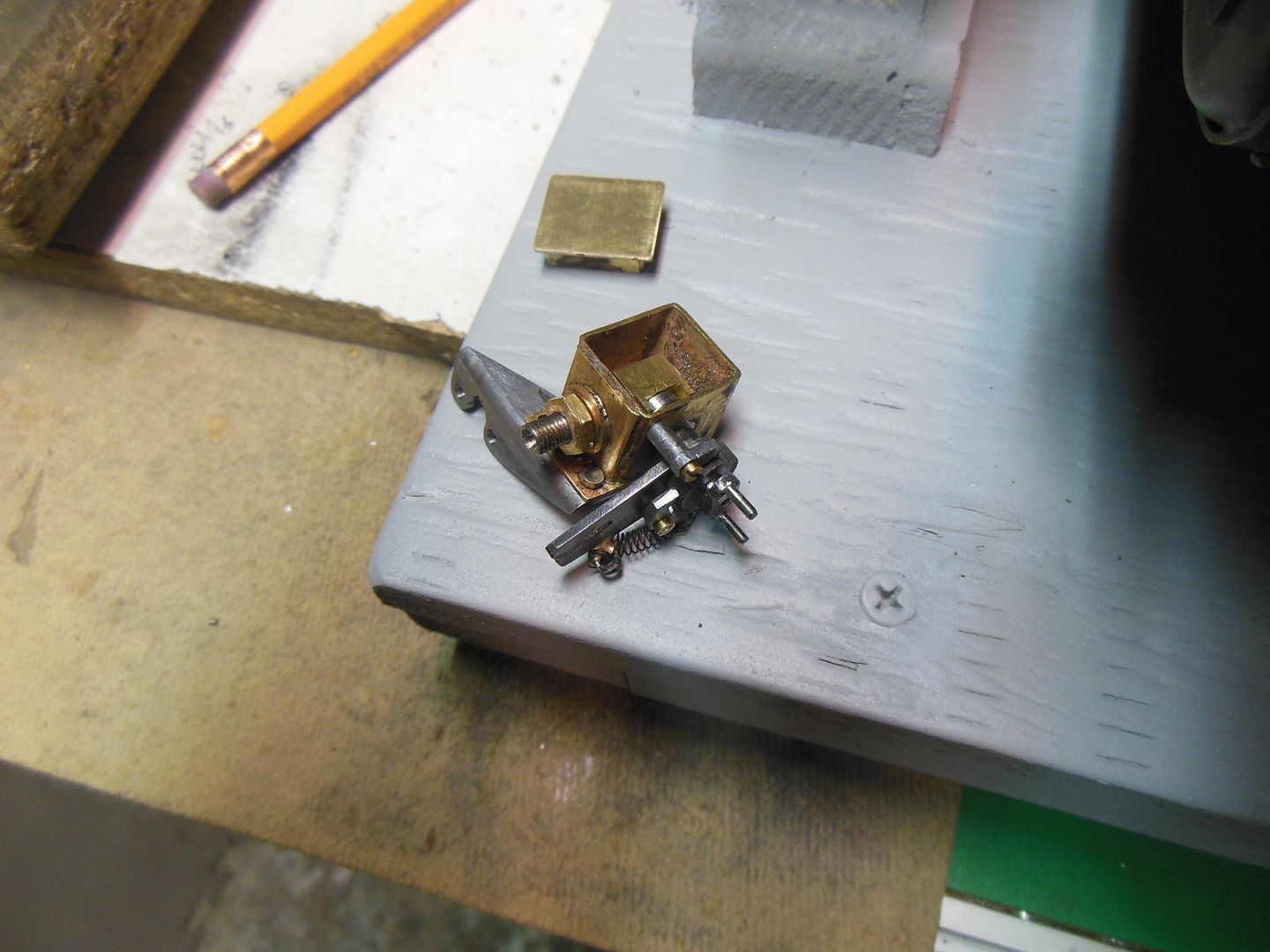

all the other bits were simple turning or drilling, bending and filing...

and that's the state of play to date...

have to fettle the fit of the ratchet dogs, get the springs sorted, and make up the pipe and valve that join the lubricator to the valve chest, and the lever that rides the valve shaft to actuate the ratchet, then need to make up the pipe that joins the blower valve to the chimney saddle, handles for the bypass valve and the damper control rod,

and a pipe for the blowdown valve on the sight glass assembly...and then it's done, bar complete dis-assembly and painting!

Sadly, all that is now on hold, as I am leaving town tomorrow for a summer contract in Ottawa... will have the occasional week-end at home,

so hopefully will complete those last few bits over the summer and will get to painting in September...

Joe