Hello guys.

I find myself lately just making tooling that I don’t have and refuse to buy. I have an ultimate goal of having a fully stocked machine shop for gunsmithing by the time I am sixty.

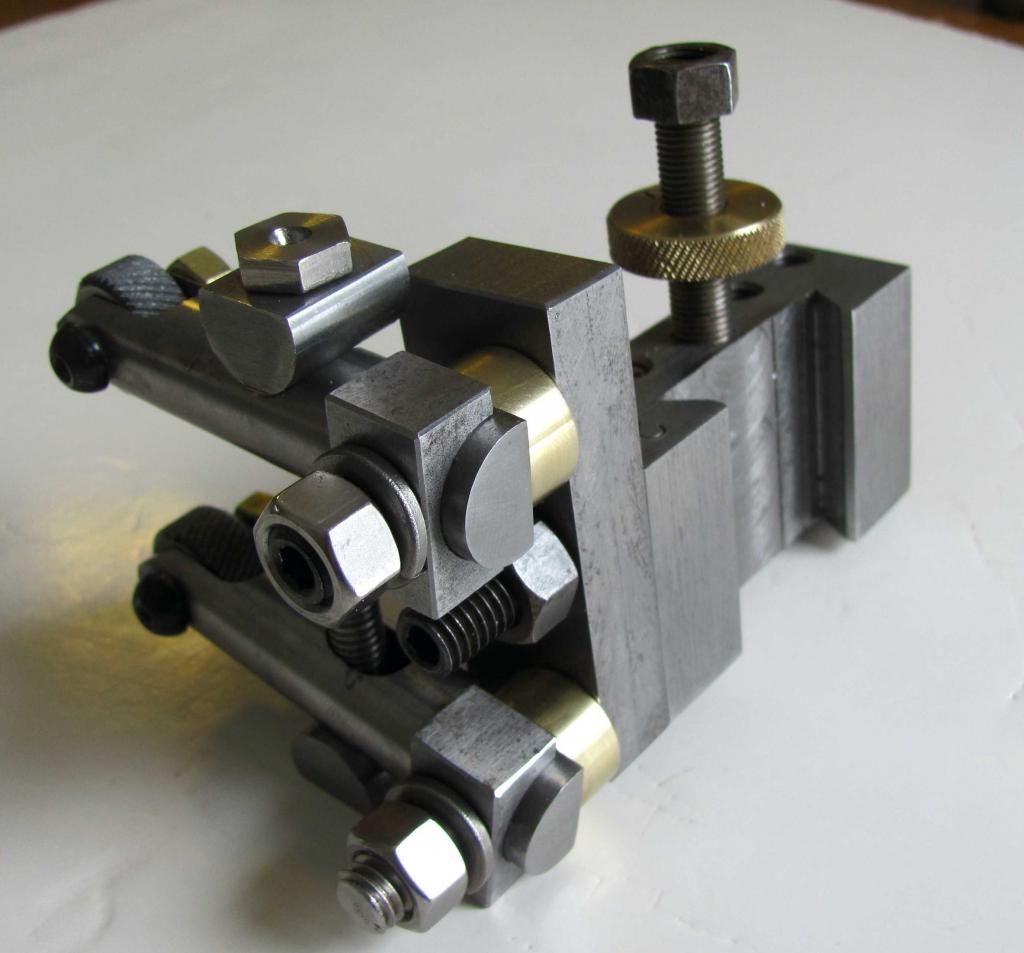

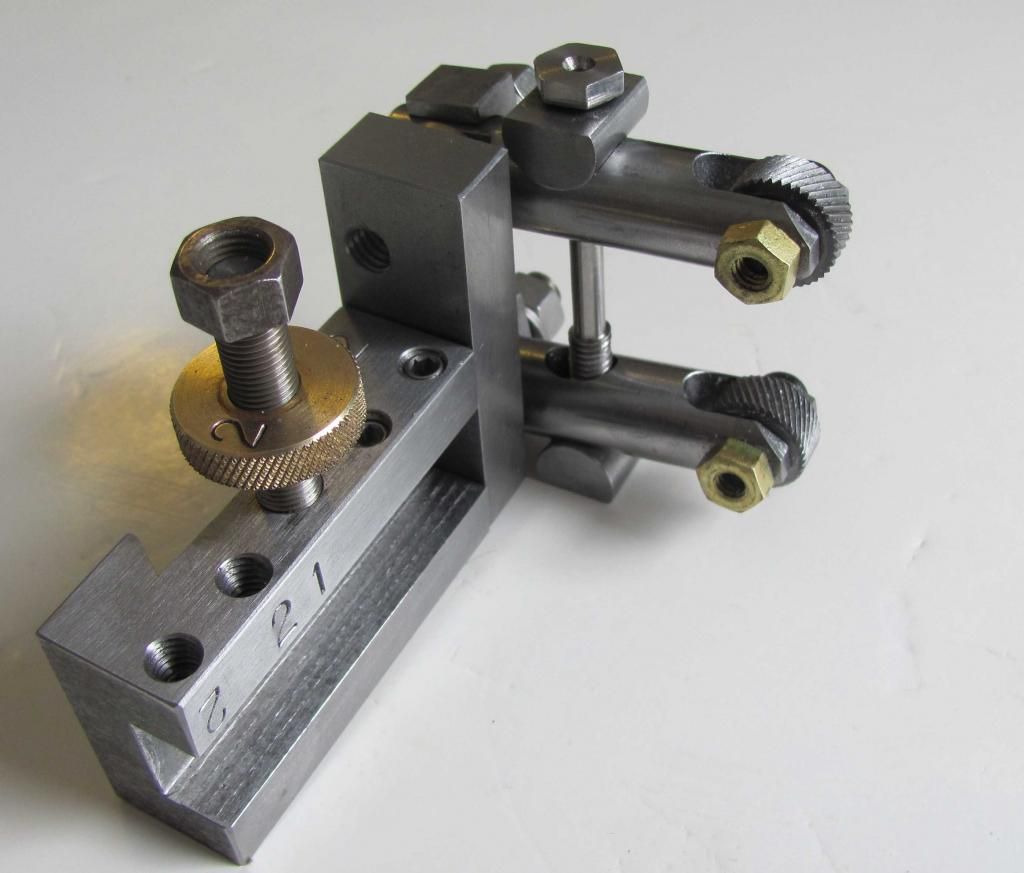

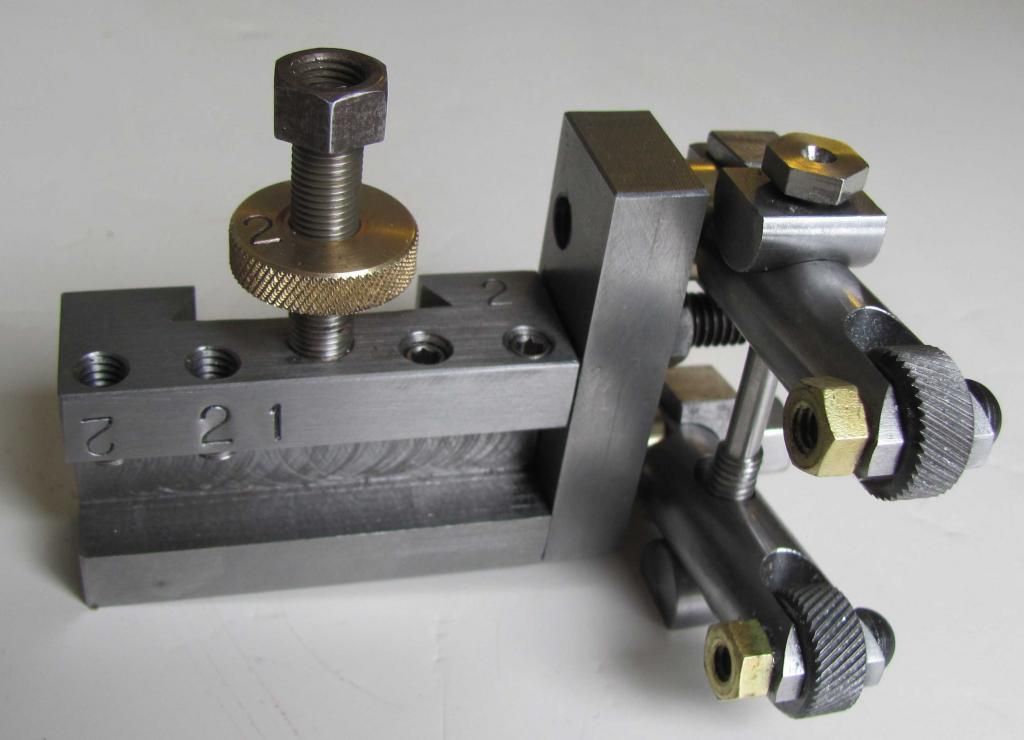

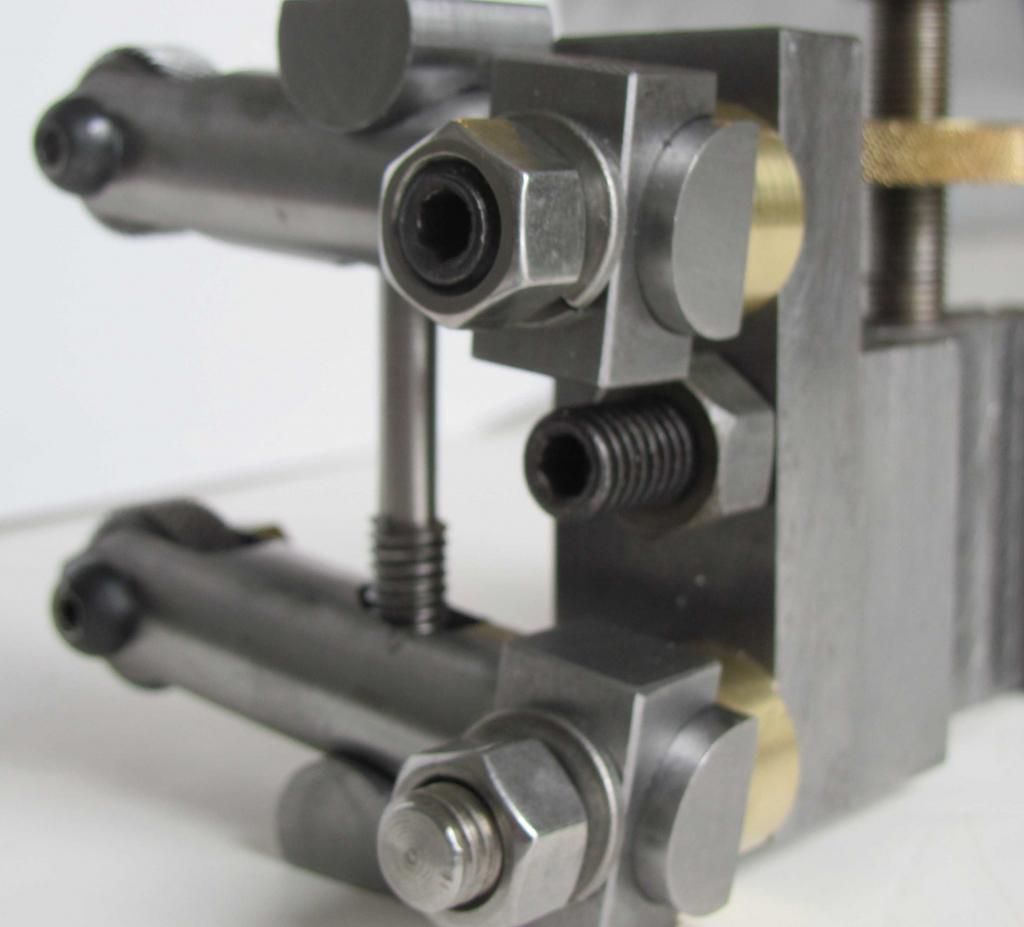

I own a Knurl tool it’s a plunge sideward force type, I hate the way it abuses the headstock and carriage. The squeeze type of knurling tool has intrigued me for quite some time now, I see the point of less work the machine has to do to achieve the knurl, so finally I got off my ass and made one.

I got plans off the net from another forum, for the life of me I forget where they come from so credit to the initial design is another, if my memory clears up Ill post his name to acknowledge the credit, I do have the full plans in PDF format which I have no problem sending to anyone if they wish, I did not stick too the original plans as I adapted his main design to fit my QCTP Tool holder, there is also some little features I added myself.

I know the nuts look ugly, i have some acorn nuts on order that will tidy up that end of it.

I was running out of Tool holders for my change post so while i was at it i made 3 more tool holders.

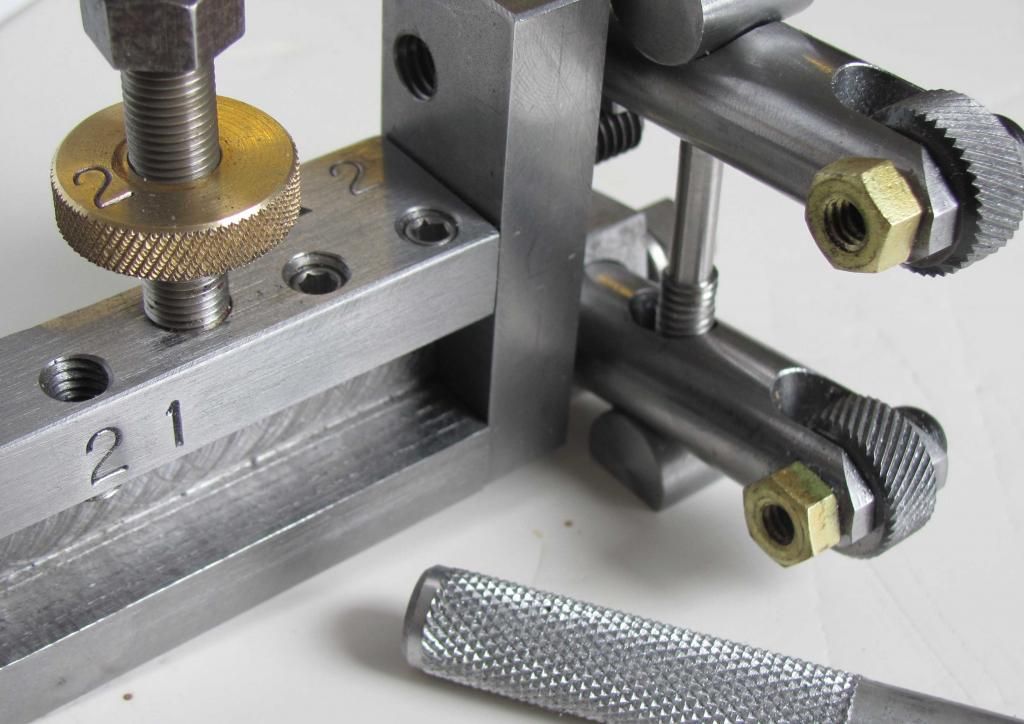

I modified it so i can expand the opening or gape, I had the locating pins(they are the ones fixed on the tool holder) 1.104 on centers and when you want to open the gape it only got to just under an inch, I needed to knurl pieces up to 1.750 dia so all I did was make a riser plate and add another pin .780 further up so this enables me to open the gape bigger.

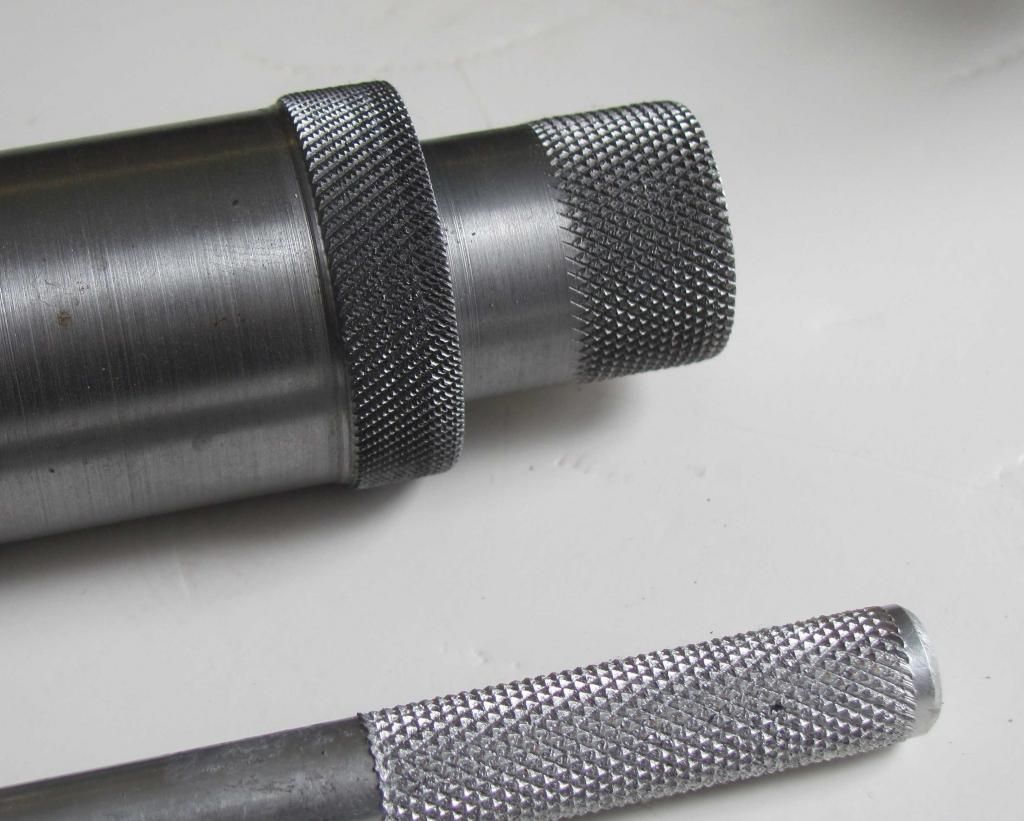

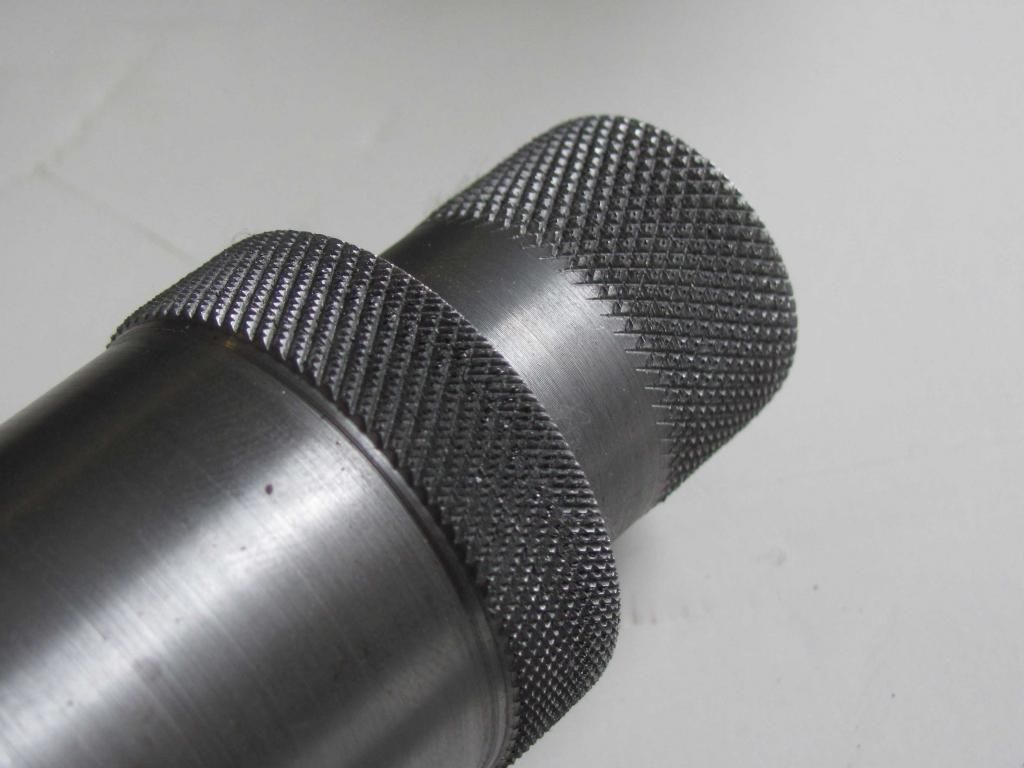

Here are the results. The top is steel and the bottom is aluminium.

So…. I needed to know how to use the tool, I suspected there was a way to do it so I did my research and found a guy in Australia who has a You-Tube Vid on how he does it, what you do is with nothing running you position the wheels over the work, you gently squeeze the jaws down just so both wheels rub and rotate a hair, then pull the tool away from the piece, then turn your clamping bolt down ( I found mine needed about 1-1/4 turns) then fire up the lathe ( back geared lowest speed and feed) plunge the tool in and make sure the wheels are at TDC, spray lube on and start carriage feed. If you need more depth (as I did) just while its rotating apply some more pressure.

I am happy with it, I now need to buy more types of patterns for it.

All the best……. Anthony.