It's been awhile since I wrote, I've been having a spot of health problems, a lung infection, three days "observation" in hospital the week before last, antibiotics, I'm tired, but on the mend, more scans next week. trouble sleeping, but that's not new!

First thing I had trouble drilling 5mm to thread M6

Isn't the correct tapping drill for 6 mm in steel 5.2 mm ?

Dave.

Dave, 5mm is the general used size. I have come to the conclusion that my build up material was work hardening, the deeper I drilled, the harder it got as despite frequent oiling it was getting hotter and hotter in there!

Discretion being the better pat of valour, I decided that it would be easier to cross drill the dial and put a slug of Teflon in the hole with a grub screw to put pressure on it to give adjustable friction on the dial.

The white lump is a Teflon off cut, I put it in the three jaw on the little Emco, turned it down, I had to finish it by hand as it was too soft to go all the way down to 5mm.

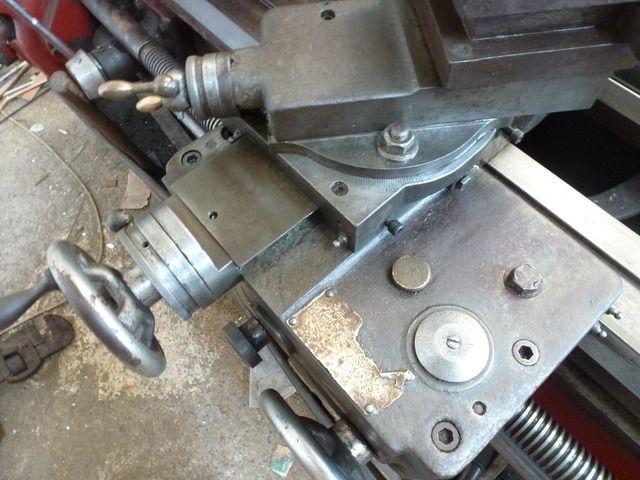

Reassembled. The previous owner had treated the oil nipples as grease nipples, cleaned and oiled up it's a lot less stiff. The "pear" handles bent back very easily with a piece of 30mm pipe.

I tried to clean up the threading dial, now it's illegible because the engraving is really shallow, when it's turning you just can't see anything, not even the lines!

AdeV, did the seller of the other Edwick ever get back to you, good thinking on your part. Each time I go to look at something, you've been there before! Like you, I didn't know any thing about the oilers, other than they are not grease nipples (grease zerks), I was able to benefit from your experience once again, I've ordered a pump type oil can that I should be able to adapt as an oiler.

regards, Matthew.