I got an Aldi weather station a few days ago to replace an old one that had gone faulty. One issue I had with the old station was the outside sensor hung on the workshop wall and got cooked in the sun. So this time I thought I would have a play at a solution.

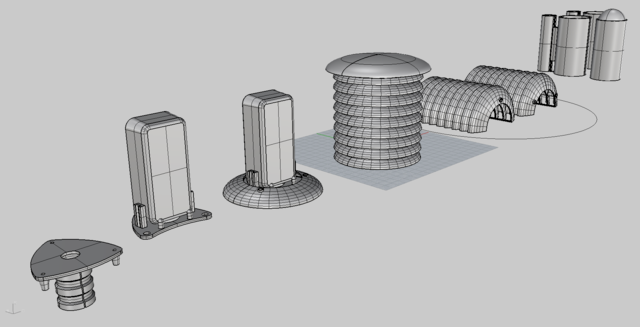

I started with a vague idea and drew the sensor in CAD as my starting point.

The above was pretty much at the end of the design process. In reality I started with the sensor, then the top and the rest of the design grew during the printing of parts. No real plan from the start and even contemplated the layers printed in two complete halves.

I had printed most of the parts and used three carbon rods to hold everything together, they are a tight push fit into the top.

Next came the sensor mounting plate, pick up the spacers between layers for this plate to attach too. Hold the sensor in with tie wraps, easy to change the batteries when needed.

Last part to be printed is the base. This part picks up the three 3mm carbon rods and attaches to the 19mm alloy tube I am using,

Couple more tie wraps to secure to the post, in reality not really need as its a firm fit.

Now installed and working. The whole project took about 16hrs, designing the next parts during prints of the previous parts. The material used is PLA printed in 0.2mm layers and this is also a test to see how it holds up to the outdoor environment. The top plate has a coating of bees wax to see if it helps reduce UV damage and water resistance.

It was a nice quick project making something useful and try out some new ideas.

Joules