Hopefully this one will lead to domestic bliss...

A disaster with the oak floor meant it needed relocating to a better room. Once I repaired all the board edges and removed the sheared screws

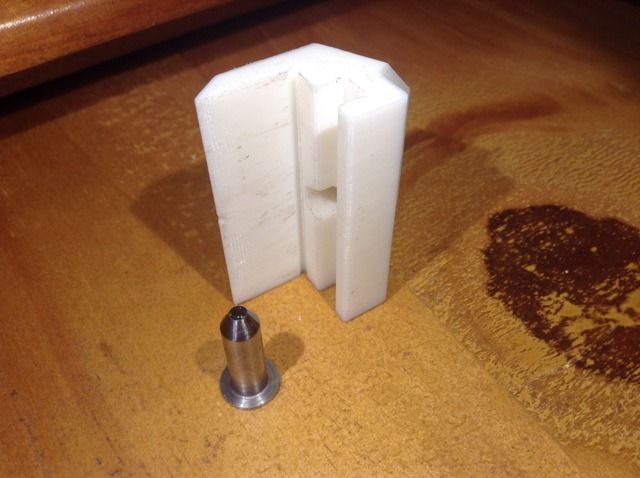

It was time to design and print a jig for drilling the boards so the screws don't find any cables or pipes when its fitted onto bedroom floorboards.

Draw the profile of the oak board and extrude the curve to create the solid model, then remove a 6mm rod from the 3D model to complete the jig body. Silver steel top hat to guide the drill.

The top hat is a nice firm fit in the print, it better be as it has around 400 screws to cope with.

27.5 degree pilot hole, that'll do nicely.

Test screw installed and no splitting along the tongue. The jig took a couple of hours to print as I wanted it to be pretty dense, but as I still needed to model the idea to get the angles and dimensions right it's still a fraction of the time (for me) needed to machine one and make the insert. I find the 3D printer really handy for these type of jobs, no hunting round for suitable stock and virtually no clean up after printing. That reminds me, I need to clean the swarf off the lathe now.

Joules