Ok, before this goes any futher there is a disclaimer and a bit of advice....

Disclaimer.... This is not my best work (by a long shot) but it works well and no one got injured! please don't barage me with "that's not very good" messages, I already know this!

Advice.... Don't rush to get things done.... That's when things go wrong!... This time nothing real bad.... Annoying but not bad!

Right... Now on with it!

I purchased a new verticle DRO from Harrogate last weekend so decided it needed to be fitted.... This is how I did it (relax, not many pic's some didn't turn out?)

First, what do you do with a new DRO....

Well I wanted to get the holes right!

Missing is the brass mounting plate pic's... Don't know where they went!?

Ended up like this....

Oh... And I cut it's head off..... It was too big for my machine (wasn't sure and this was only bout a quid dearer than the short one)

Next, cut off a slither of aluminium 100mm bar 9mm thick. Face off leaving 7mm plate. 4 jaw ofset and centre drill.

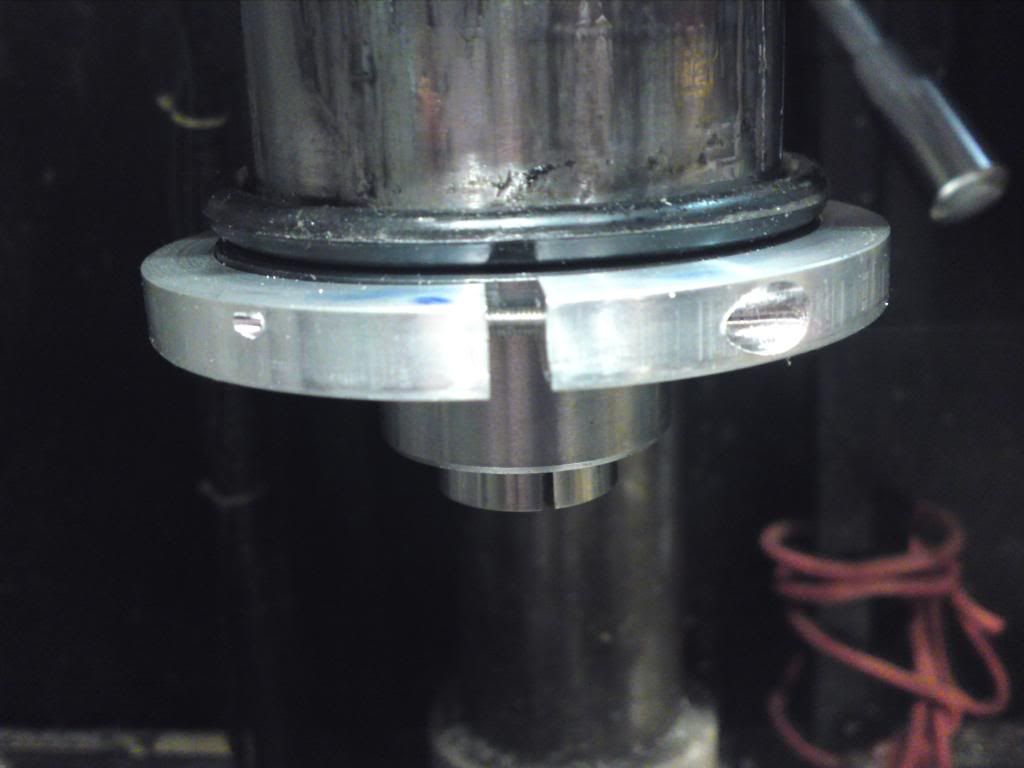

Bore out the centre to allow plenty of room for my spindle (Note the classy saddle stop!!)

next adjust the saddle stop and remove a 72mm area 5mm deep from the disk like so...

set up in the mill centre drill and drill through for the thread (this is where the issues started)

Couter sunk for the bolt and drilled a clearance for the bolt thread to pass through upto the centre.

Then snap a tap in it as you do!!!

So... After I'd returned to my state of inner peace I did this....

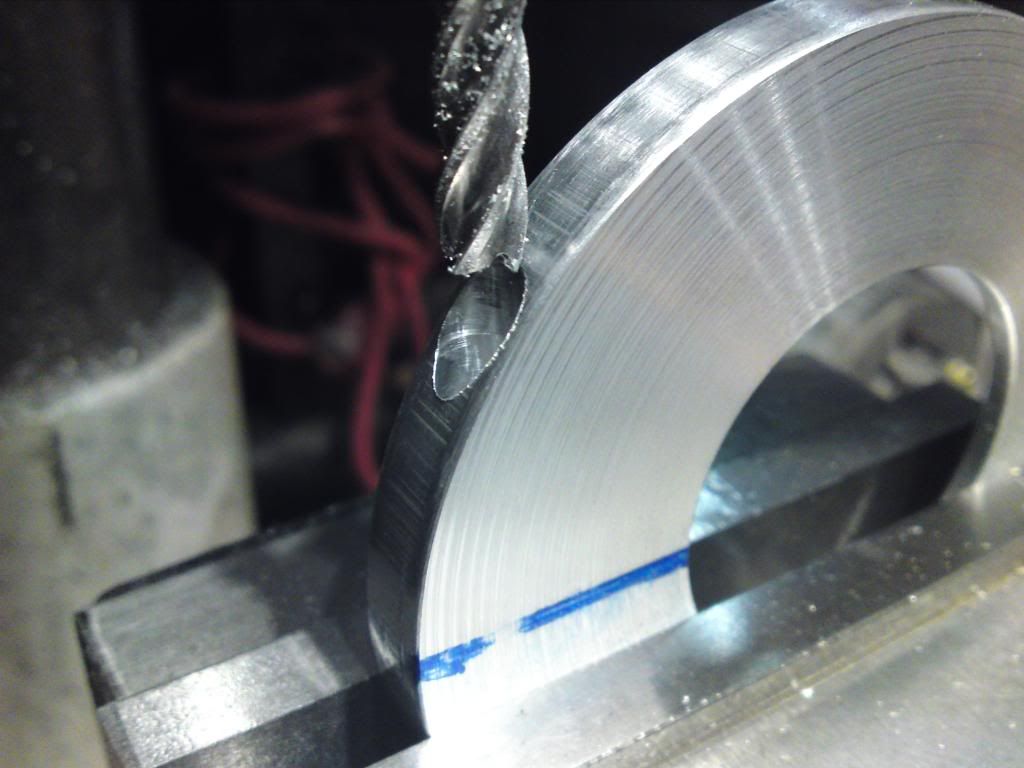

milled with a 3mm endmill down both sides of the broken tap and used a thin pair of pliers to unscrew it from it's position!

It needed a slit here anyway.... This was just a bit wider than planned!

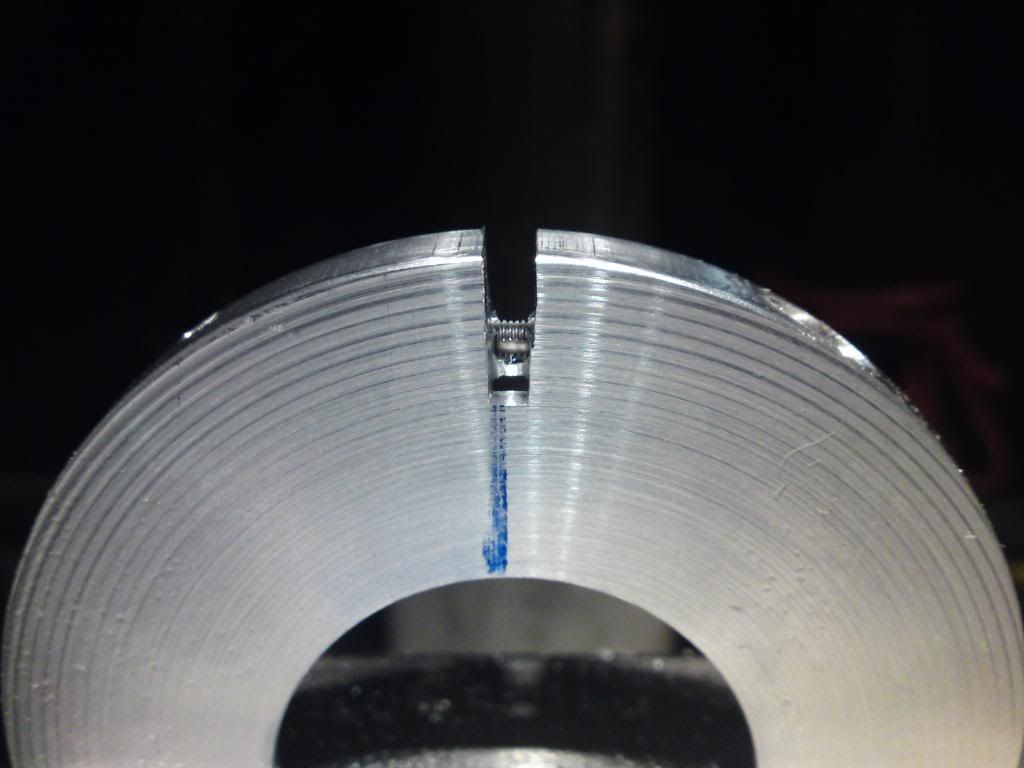

I ran a slitting saw through the remaining material and then test fitted it to the machine

The reason for the broken tap is obvious... The long series drill bit I used deflected on its way through.... tap was stressed as I sent it through.... It looked ok from the front!!

Still.... All dramas over with..... It does work

I could have re-made it..... But it's perfectly functional and will not be removed anytime soon

Ralph.