Here's an update on the engine. I wanted to built the exhaust from .375 stainless tubing. I didn't have a bender sturdy enough to do the bending so I had to make another one. In my experience bending tubing, even with a good bender I get somewhat of a flat on the outside radius of the pipe. I spoke with a fellow builder and asked if he had ever used Cerro alloy to fill the tubing prior to bending. He said he did and had good luck with it. I ordered a small cube from Ebay (expensive stuff!)

Once the alloy arrived and I had the bender built I set about bending the tubing. I put the alloy in an old coffee can and put this into boiling water, the alloy I got has a melting point of 154 degrees. I filled the first piece of tubing and when the alloy cooled I took it out to my big shop vice and proceeded to try out my new process. I clamped the tube into the bender, put a 12" adjustable wrench on the lever arm and started bending. It bent much easier than I thought it was going to. I took the piece of pipe out of the bender to check the bend, wow, absolutely perfect, no flat spot whatsoever.

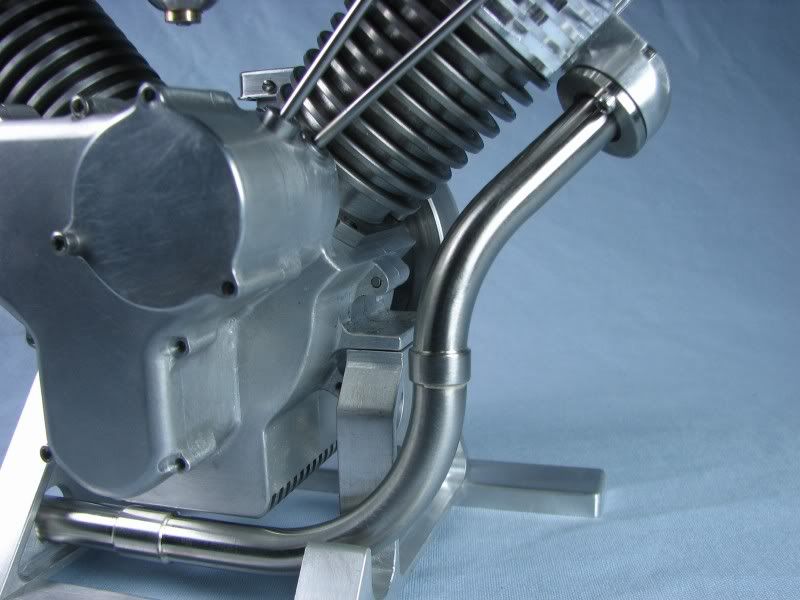

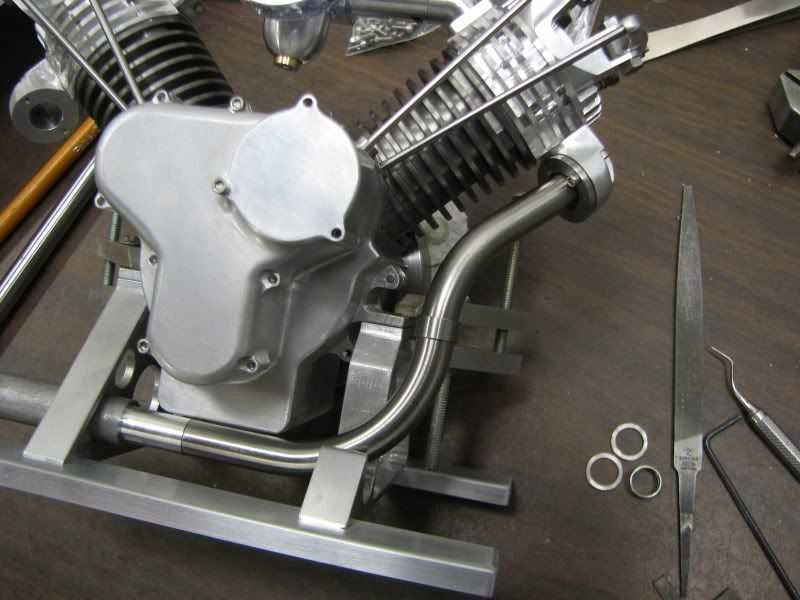

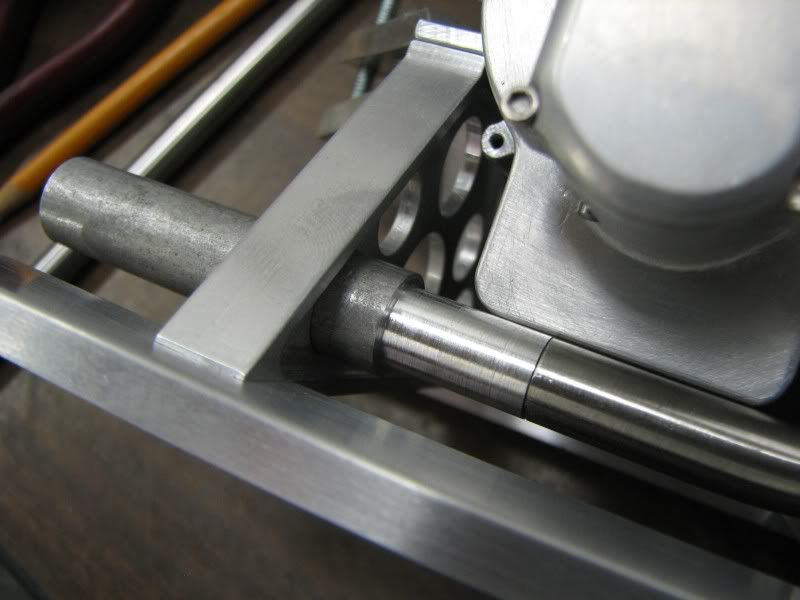

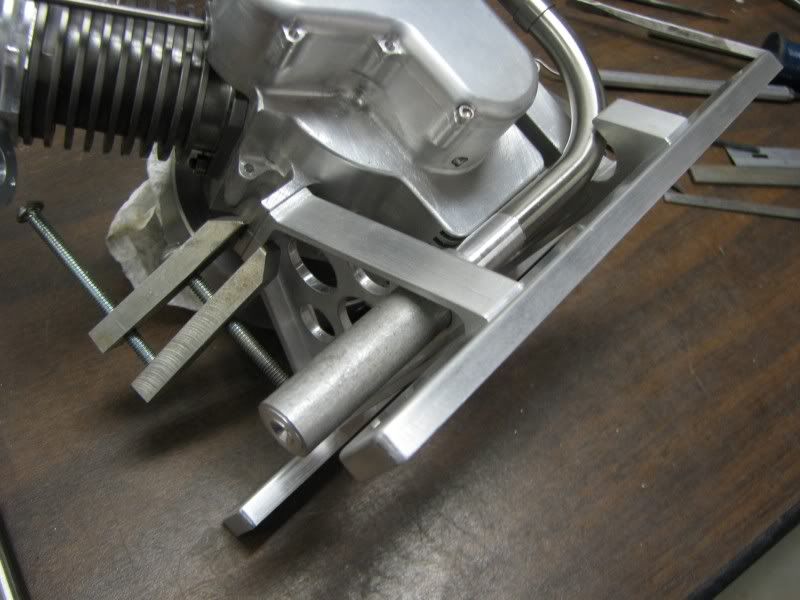

Now it was just a matter of making up the other bends and slowly fitting everything together. Being that the front exhaust pipe had to pass through the motor mount I decided to make it in two pieces and silver solder it together. The construction of the bender and the radius that I used wouldn't allow me to get two bends close together and beside that I didn't know how many pieces of pipe I would go through trying to get a good one.

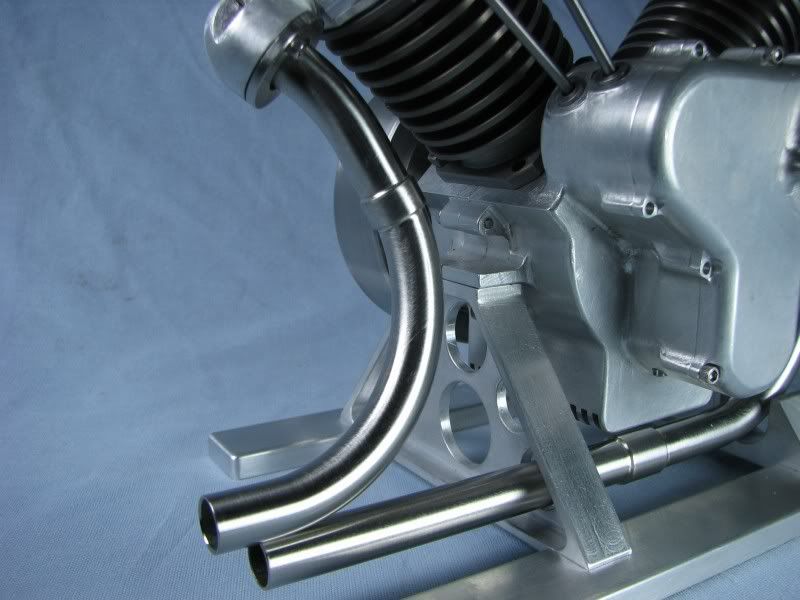

The rear pipe required different bends than the front pipe because I wanted it to stack on top of the front pipe. I think I have about 24 hours in the bender, cutting the tubing, filling with alloy, bending, melting the alloy out, filling and fitting the pieces and silver soldering everything together.

I must say that I am quite pleased with the outcome. Even with the small connecting sleeve on the pipes I think it looks good.

The first several pictures show the fitting up of the front pipes. I turned down a piece of aluminum to locate and support the pipe for soldering.

The next pictures show everything polished and assembled.

George