The point is the source of the DRO error most likely is not backlash, and that the error is therefore likely very small.

If you connected the scale to the quill, it is separated from the backlash, just as if you connect a DRO to the axis of your table. You can turn your handwheel all you want in the backlash zone, and because of the backlash, nothing moves, hence the DRO stays put and is not affected by that error. As I say, this is why we like DRO's!

Now as to the accuracy of the DRO beyond backlash, that'll be a function of the scale you're using. And it's worth checking it. Certainly you can buy a really expensive scale that is particularly accurate, but the scale I've got has always read to about 0.0005 and it's just a cheap caliper I converted. I'd be surprised if you're seeing 0.002 errors from such a caliper properly mounted, but again, it's all a function of the scale you're using. If I found one out 0.002, they're cheap enough I suspect I would toss it in the trash, LOL!

As to the question of locking the quill, it's really in the same category as the backlash. If the DRO measures the position of the quill, you can lock or unlock at any point and it will reflect whether that action moved the quill at all, and hence it is factored into your tramming. It's a little frightening how much a lot of quills will move when locking and unlocking, so I regard that as yet another reason to want to have a quill DRO. You'll eventually get good at knowing how far the lock will move it and you'll account for that in the position you select before locking. All that becomes pretty second nature once you've used your quill DRO for a little while.

In essence, then, this approach is kind of like using your quill as an erstwhile height gage.

With all that said, I'm not advocating you tram this way. Tram however you'd like (and I especially won't bring up tramming with a Coaxial indicator after reading that "other" board's thread, ROFL). I'm just saying the Quill DRO will account for most of the errors people are bringing up as worries and won't affect your tram. If you guys are reliably tramming closer than 0.001 on these cheap mills, my hat is off to you and I hope you've got your Interapid tenths indicator handy to do it with!

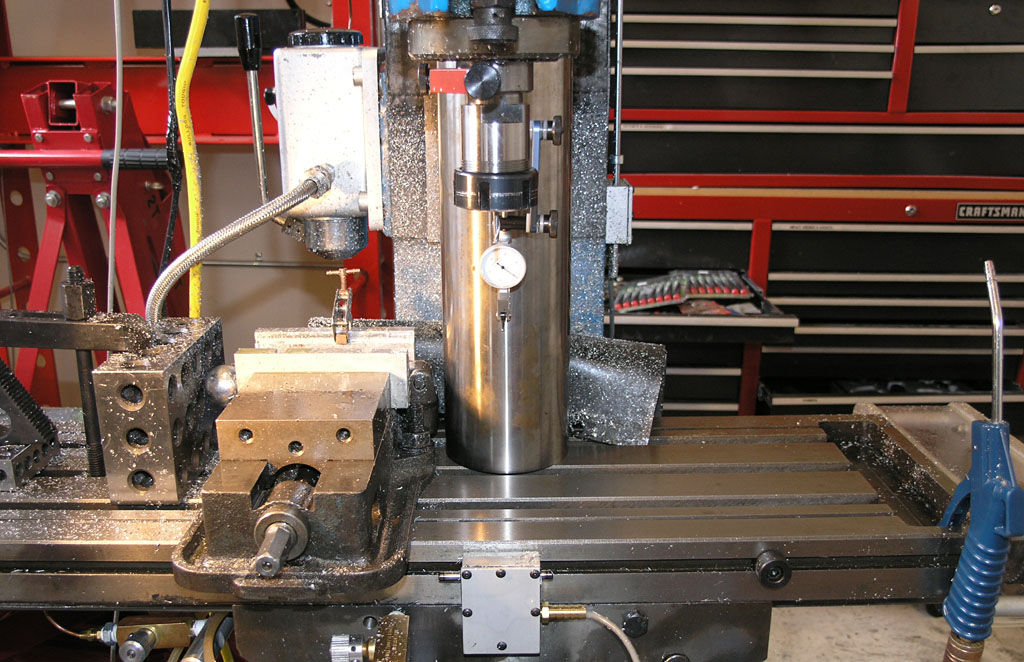

I've played at that end of the pool too when I squared the column on my mill:

It's an awful lot of trouble just to tram things though.

Cheers,

BW