Started on the frames tonight, or standard as the designer calls it. I bought a length of 1" x 2" aluminium for this. The idea is supposed to be to machine the profile on the end of the bar sticking out of the vice, but my vice doesn't grip when at it's maximum opening - I remembered having problems with my cylinder for the last flame gulper.

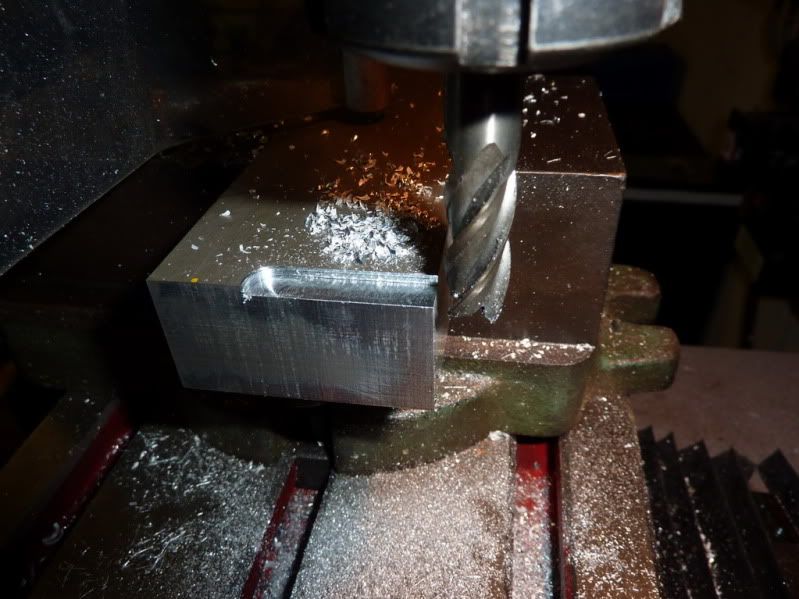

So I had to flycut the material down a bit first:

First time I’d really flycut anything and it went well, or at least I thought it had but when I measured it, the bar was about 20 thou different end to end. The milling machine is cutting on a taper – which means either the vice is not made properly, or the milling machine is not made properly – I’m guessing the milling machine. When I got my machine 2 of us bought the same one to get a discount, I know the other guy had a problem with his table being tapered. Will have to check mine now.

I could now remove the jaws from the vice to get a bit better grip (faulty vice) and grip to mill end square:

Next I milled the bit off the end leaving a radius, this took a while, I was taking cuts of around 3/32 – 1/8”:

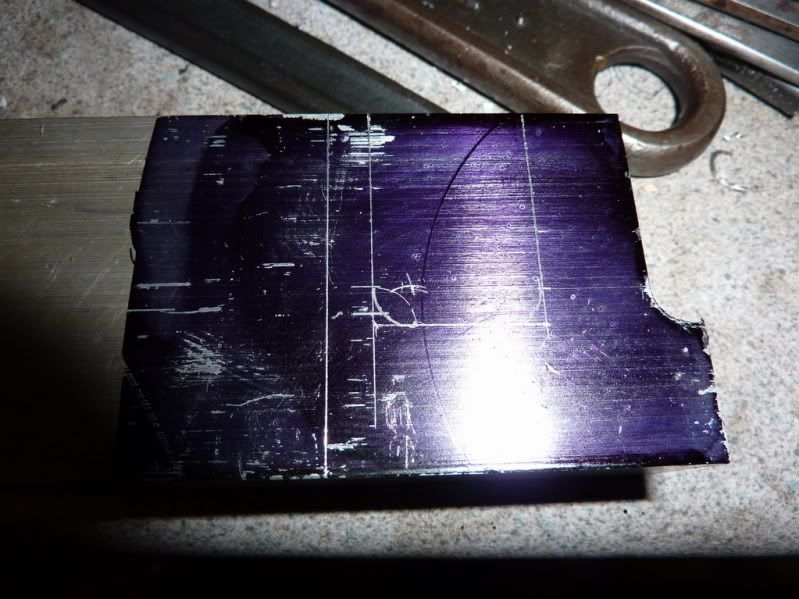

I then decided to mark the thing up as it was a pain trying to use the graduated dials – and I know they are not that accurate, really need some sort of DRO setup:

I then started milling the other section out to leave the 2 rads, but this is as far as I got:

When I went to mill along, the metal moved in the vice again – no damage done but just no grip.

Whipped the end plate off the vice and found this:

The casting has cracked at some point leaving only half a nut for the screw to screw into – hence at wide openings if you try to get a decent tightness, there is enough play in the bearing to let the screw ride up on the threads and jump out of mesh. Don’t think this will be particularly easy to fix but will have to have a look. I don’t think it’s something that’s just happened as the broken bit is nowhere to be seen. Probably always been like this, I’ve just been getting away with it for small openings as the nut is engaged closer to the bearing, hence there isn’t enough play to let it ride up and jump out of mesh with the screw.

So probably on the look out for a new vice now as not too hopeful of being able to repair this one – shame as it is, or at least was a good vice – Elliot.

Nick