Hi guys,

The lathe is a fair size and more rigid than most Dean, it's a Harrison L5 9 x 24" but the capacity doesn't tell the full story, it's bigger than it sounds! It's been a good purchase, I wish my milling machine was of the same ilk but you win some you lose some!

Well I've had a couple of short sessions in the workshop since my last post. For some reason I just can't get motivated / finding it hard to find the time, then when I do I'm in by 22:00 where as before sometimes I was in the shop until 2am - that's probably not good I know, but still got more done that way!

Anyway, onto the build:

The first job was to get all of the flywheels to the same stage with the recesses turned out, remembering to do 2 flywheels with the larger dia. recess on one side to clear the cam disc.

I then blued the flywheels and marked them up for the lightening holes by using the jaws of the 3 jaw chuck to index the 6 holes.

The idea then was to set about making an arbor to hold the flywheel on – this way I could set the milling machine to the right place then simply fasten each flywheel to the arbor in turn and index around lining up by eye with the markings, tighten nut, then drill. There would still be a bit of manual adjustment but only 1 adjustment for each hole.

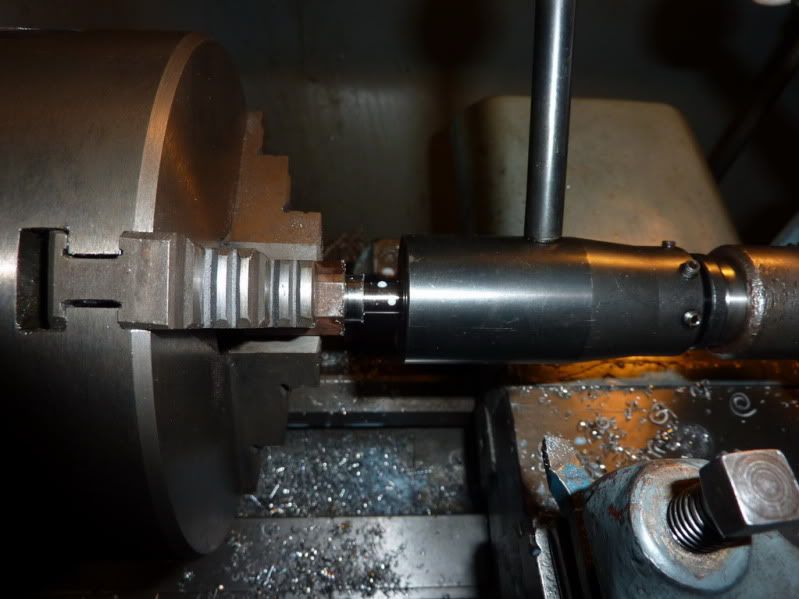

Threading arbour in lathe with tailstock die holder:

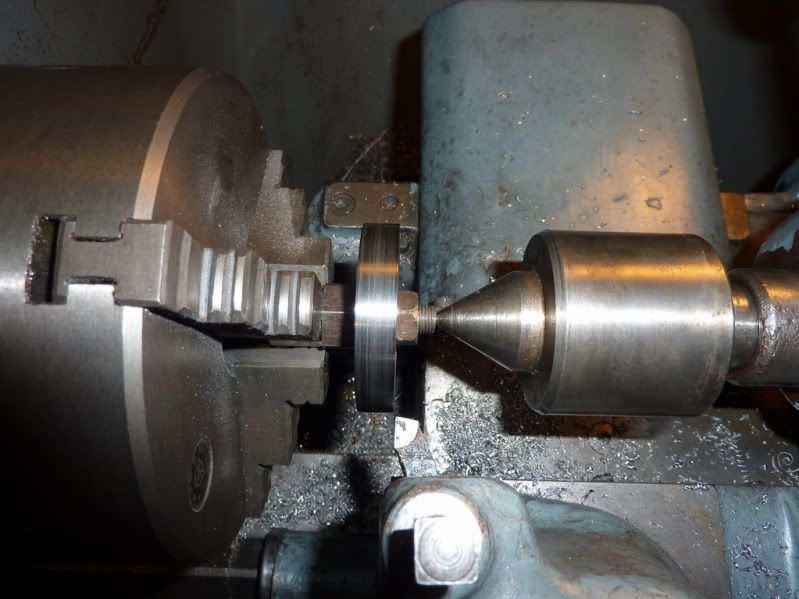

Here is the arbour:

So I plonked it in the milling vice, centred the quill and wound it out to the rad that the lightening holes lie on and started drilling:

I soon realized that this method was still taking a while – I had to drill 24 holes, 6 on each of 4 flywheels but opened up gradually too. As soon as I started opening the holes up it became less easy to find the centre of the hole by eye.

Luckily, I had a brainwave – I say luckily because by chance I had made the arbor from hexaganol bar – my indexing method was sat there looking me right in the face and I couldn’t see it!

So with a vice depth stop in place (thanks Tim!), all I had to do was clamp the flywheel onto the arbor, slacken the vice and index around onto the 6 flats of the hex bar! This made if very quick to do.

Here are the flywheel s at similar stages:

Once I got to the larger size I was having massive problems with getting the drill to cut – It did a little then just refused, with or without cutting oil, tried regrinding etc but it was making a right mess chewing through the steel on the first flywheel I did. So I used a slot drill instead, this worked much better, quicker and cleaner.

Once all the holes were drilled I put the arbor back in the lathe and turned a parallel register on the other end. Turned it around and turned a new location diameter for the flywheels (see last pic) I then left the arbor in the chuck and clamped each flywheel on in turn to true up the OD. This should make them run true.

Here are the two pairs of flywheels, I’ve left the centres as they came from the lathe so I can paint.