I wanted to make something today. I didn't have anything in mind, except I felt like something simple. Looking

at "The List", I see I have the words 'alcohol lamp' written among a hundred other things, and that sounded easy

enough for how I felt when I got out of bed this morning.

Would also be nice to have another heat source for the Duplex engine, and this should do.

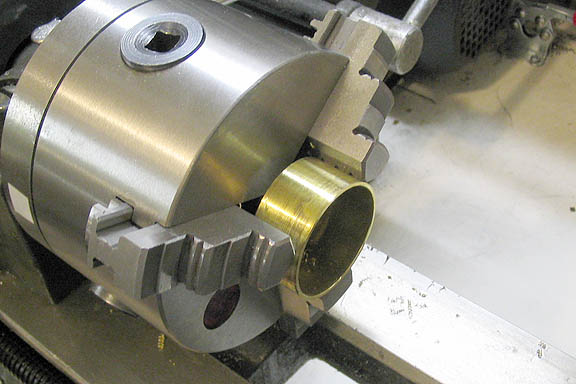

Last summer, I found this piece of brass tubing at a yard sale. It's 1.5" dia and .040" wall. It was made for

a shower curtain rod, and the guy had cut off what he needed and this was left. For $5 I couldn't leave it lay.

Cut off a piece and faced the ends.

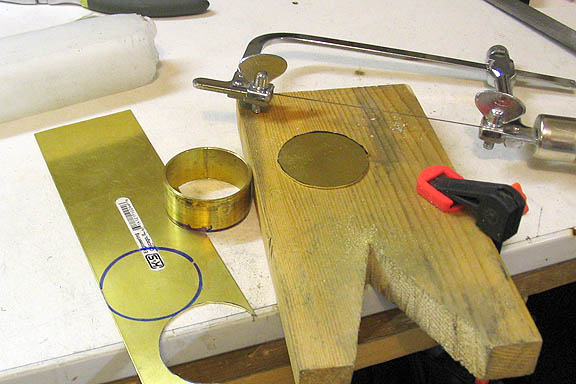

Then cut out a couple of discs from .025" brass sheet.

Silver brazed one end on using a few pieces of 45% silver bent into arcs to approximate the ID of the tube.

Well, it needs to go into the pickle for about 20 minutes.

Used a step drill to put a hole in what will be the top. This hole is for the wick tube.

I've had this step drill for years, but I often forget to use it. Every once in a while Stew or Bogs will

mention them. I finally put the thing next to my brass drill bits a while back so I'll see it.

The hole is 1/4", and I have some modeling tubing the same OD to fit.

With the wick tube cut to length, a step reamer is used to clean up the edges inside. The reamer is also

used on one end to expand the tube so that end will be slightly larger than the hole that was drilled in

the previous step. To do that, I just tapped the reamer in a few thou using a small plastic mallet.

Next step is to drill another hole to tap for 1/8" NPT. This will be the filler. I tapped it at a slight

angle so the filler neck will cant slightly away from the wick tube. Probably not needed, but I thought I

should do it, so did it.

I used a 1/8" brass pipe nipple. The reason for that is, electric lamp fittings are made with that thread.

Things like finials, little caps, and decorative dingle-bobs for people who make or restore table lamps and

such are threaded to fit 1/8" NPT. Kind of handy, and I'll use a table lamp cap for the filler cover.

Another brazing heat, and then into the pickle again.

In the above pic, the base has also been brazed on. I did that last piece with 56%. It melts a couple

hundred degrees below the 45%. I didn't want the smaller pieces coming loose on the last heat.

As you'll see, it wouldn't have mattered. A goof is imminent.

Ahhh-ha-ha-ha! Ugh. Very funny. Obviously, something didn't go right when I was finishing this up

in the lathe. This stuff happens, sometimes. Nooo, I wasn't on my meds. Not when I did this stupid

thing, anyway. I was taking bitsy little cuts and all was fine. Then I bumped the cross slide handle

as I backed out of the last cut, and suddenly, Chubby Checker was singing "The Twist".

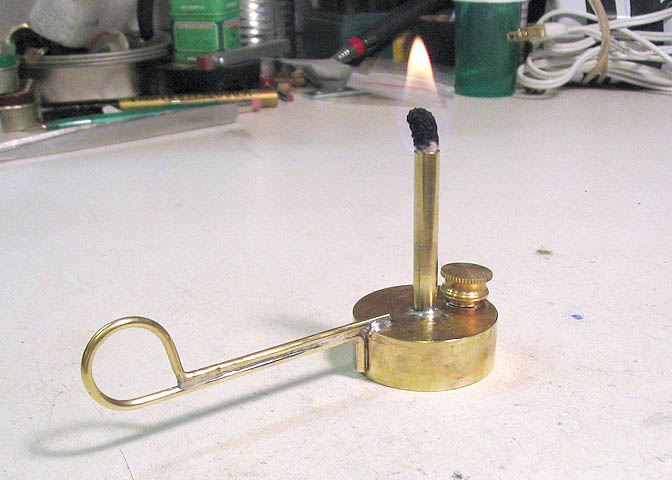

So I fixed it. Filed off a bit of the threads on the filler and cut off the wick tube. Putting in the

new wick tube, I just used regular solder. Also made a loop handle from 3/32" brass rod, and put it on

with regular solder too. None of this needed brazing silver anyway. I did the other parts with it for

the fun of it, and for practice. The whole thing could be done with plumbers solder.

Well, it came out okay, after all that. I'm not very good at polishing all the pink out of heated brass,

but it will have to do.

I don't think it will hold an ounce of alcohol, but it burns for over 15 minutes.

Last time I made a lamp type thing, it was the small Jerry Howell propane burner.

Then I had to make an engine to go with it...

I tried this little lamp in the Duplex engine, and was surprised at how well it worked. As good as the

propane burner I made for it, and seems to keep a steady speed better on the alcohol.

I let it run for a timed 7 minutes, then blew out the flame, as nothing unusual seemed to be

happening, and I got bored.

I made a short vid at the end of that 7 minute run, just to show it will run on the juice.

Stew asked about that! Yes Stew, it runs on the booze!

Thanks all, for having a look.

Dean