This was one of my first projects when I was getting familiar with my mini-lathe and mini-mill, and before I did

anything to tune them up.

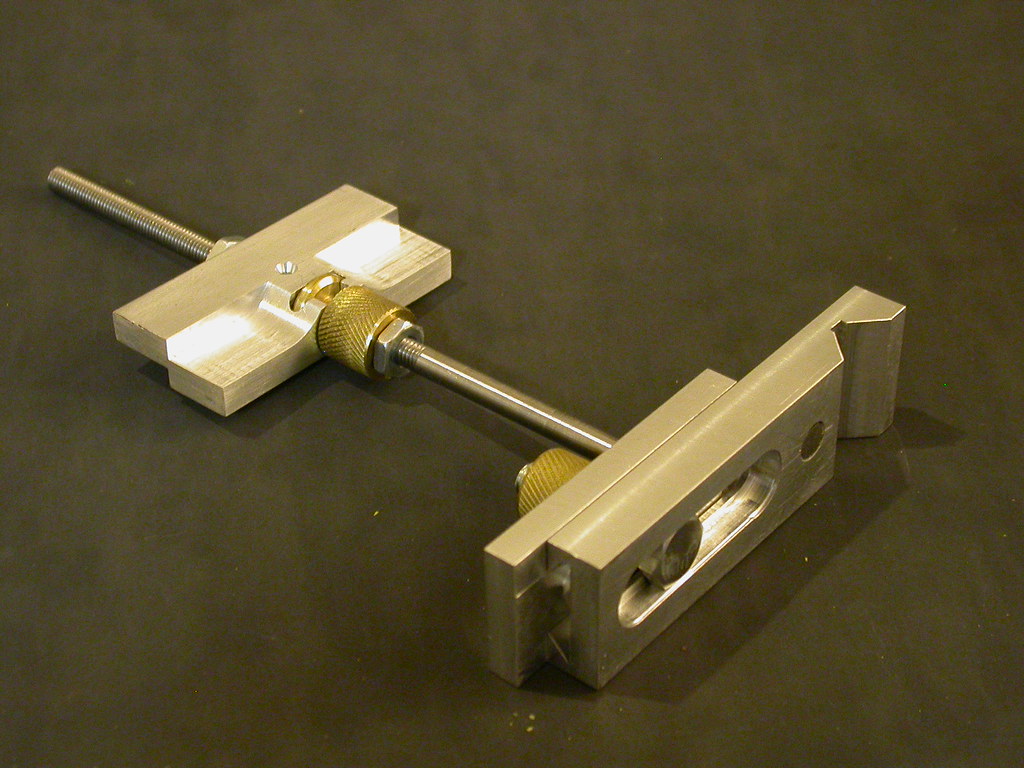

I wanted a device that would let me raise the tool to the centre line, and mark its positioning on the Y axis so I'd know where the centre was for facing. Here are my comments from when I posted the photo on Flickr:

This is a tool for the lathe, but was mostly made on the mill. I don't know why, but I kinda went overboard on this. I wanted a reference for the axis of my mini-lathe, something I could move up and down the ways and against which I could adjust tools and centres. This is what I came up with. The base has a 'super'magnet inset to hold the unit against the ways; there's a channel milled for the ways' diamond riser, and the centre has a through slot for a 1/4"-20 bolt and a shouldered slot for the bolt's head. The top is dovetailed for the rider. The rider is positioned forward/rearward to match the lathe's Y axis, and locked in position with the brass 'nut'. It has a #10-24 hole tapped for the base of the stand. The top of the stand is threaded #10-32, the alignment fixture moves up and down with the brass traveller knob, and is locked in place with nuts above and below. Locking just the bottom nut allows the fixture to rotate in place. The fixture is the oddest part of the unit; it's meant to allow alignment of tools whose tops must be on the centre line, tools whose bottoms needs to be thus aligned, and conical things. It rotates around the stand so it can serve these functions for both right-hand and left-hand tools.

It may not be clear, but the slot for the

1/

4" bolt is just as wide as the bolt-head's flats, so the bolt is kept from turning.

It looks a lot sexier in the photo than it does in real life.

While it was an interesting exercise, it's not really up to its intended application; the ascender isn't guaranteed square, the reference surfaces aren't definitely repeatable on rotation, and it doesn't sit completely flat on the ways. Plus, it was machined with tools that weren't themselves precision-assured.

But it was fun.