Scott,

I can't get that video to work? But I know about metal spinning. I have the DVD set from the 'metal spinning workshop' instructional videos from Terry Tynan.

I have just got to find the time to make the rest and tools... It will take a lot of work to make some of the stuff required.

I'm taking the press approach for a few reasons... 1] I've got it. 2] it's a challenge that I've never tried. 3] I've still got a lot to learn but....

This evening I've been having fun!!!.....

To start with.... My first ever use of a face plate, I've been taking notes Bernd.... Sacrificial ali plate used between work and face plate.

I cleaned the edges up and then bored it out for the punch to fit through (eventually with the collar on, I think?)

Finished plate.

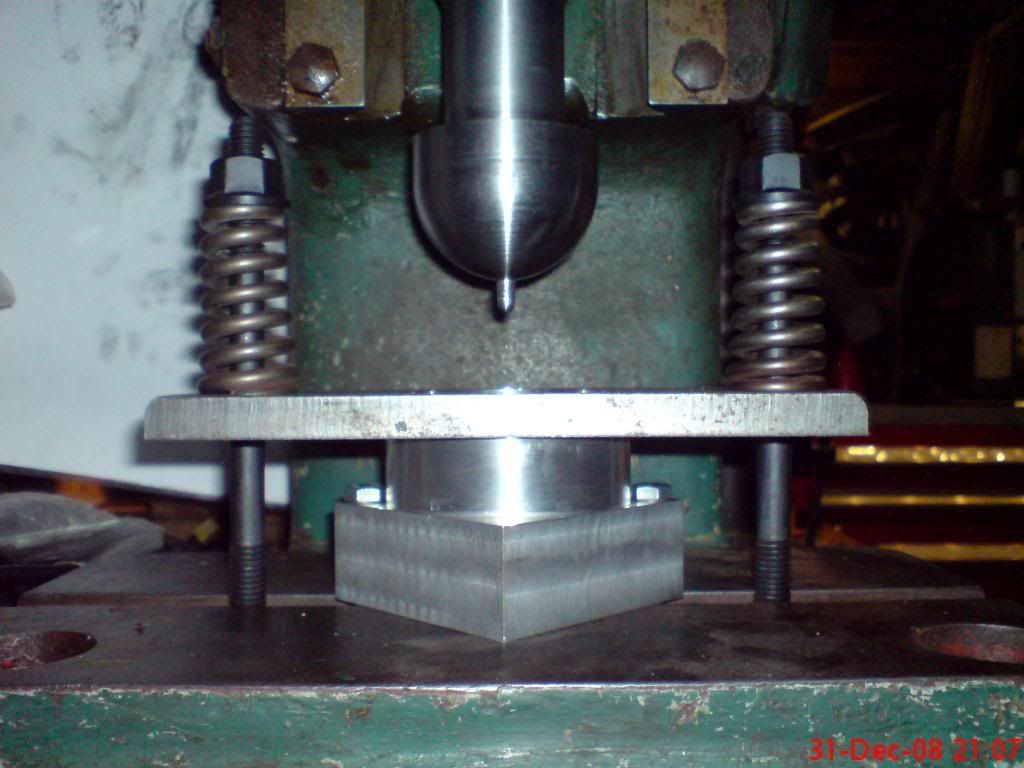

I mounted it to the press using long bolts and some powerfull springs... As I figured might be needed after all the discussion earleir in the post....

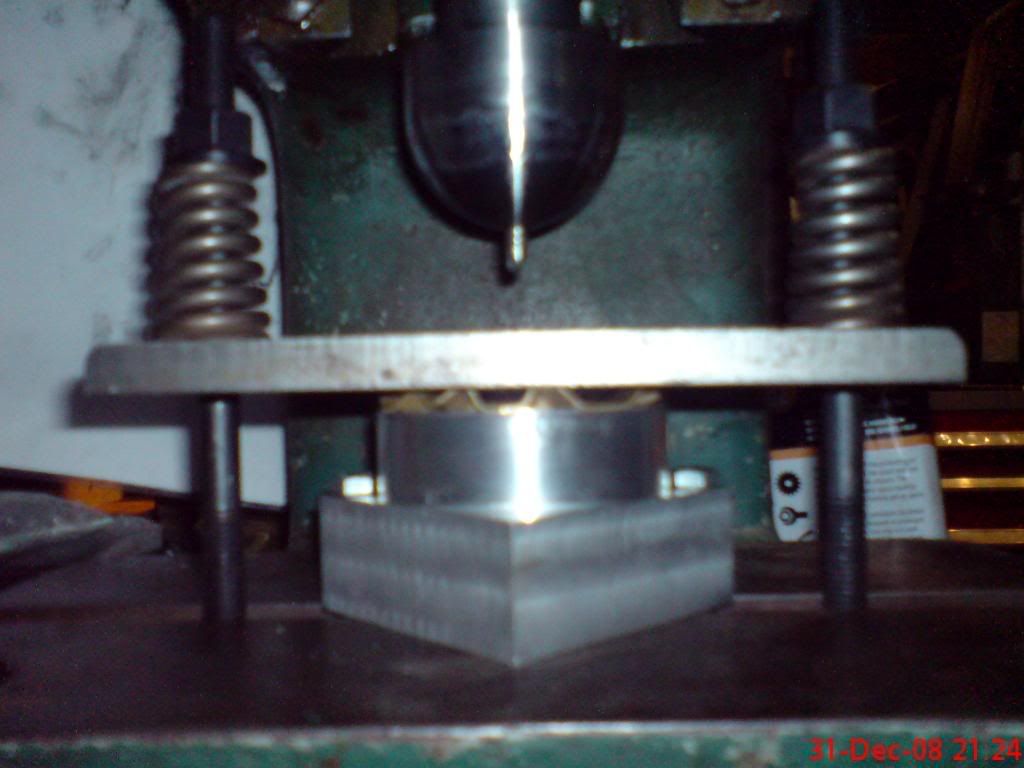

Well I gave the press a good hard go and it did this....

The springs did alter the amount and style of the creasing. It also kept the domed form quite well, even if it didn't reach the bottom of the die!

So I tried it without the springs and the plate tight ....

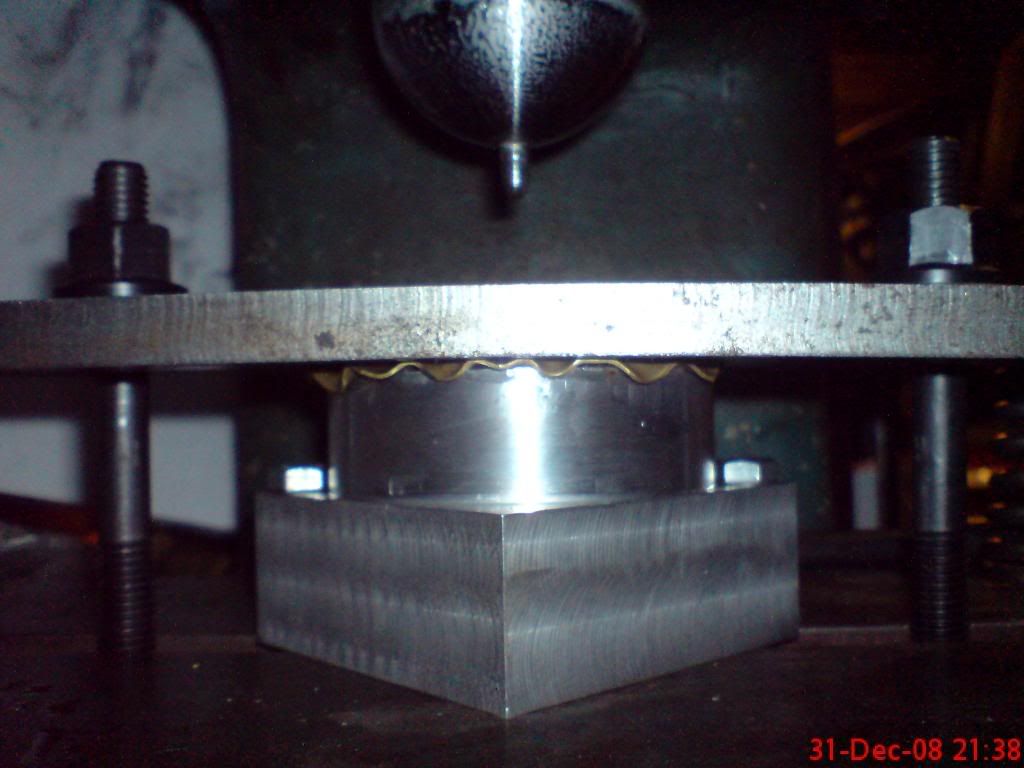

And the results.... Non springs one is on the right.

Well I'm not down hearted... This was brass 0.7mm thick... I've got some copper 0.5 and 0.7mm on the way next week

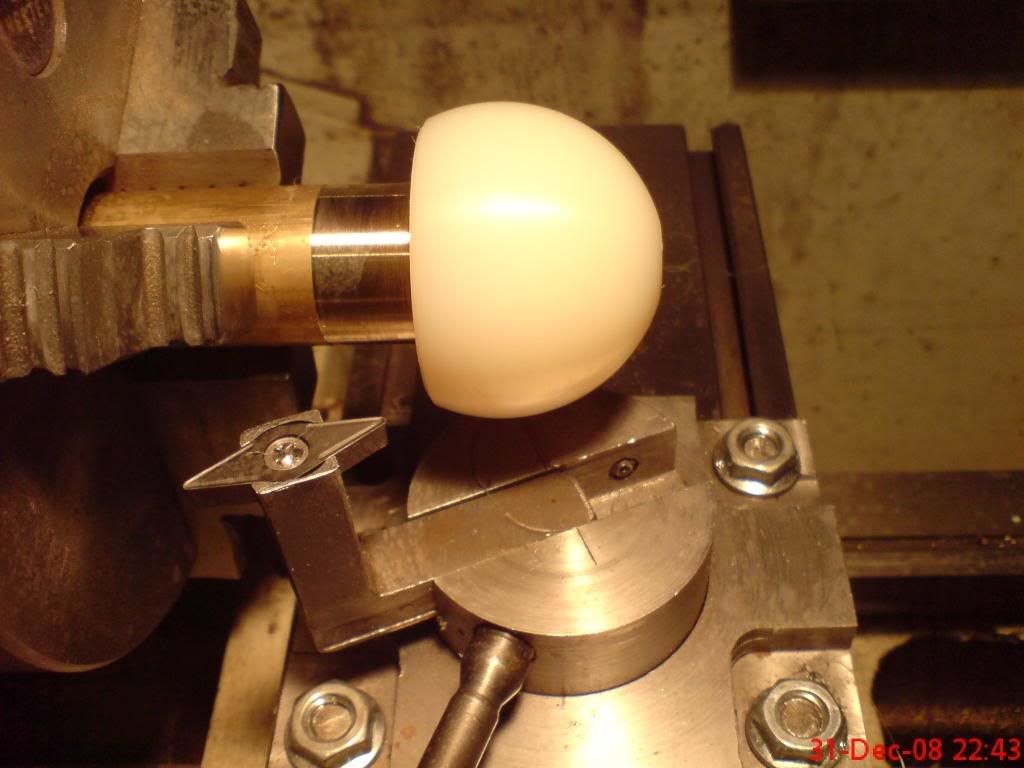

I decided that since I had two near forms I'd make some of the other tooling required....

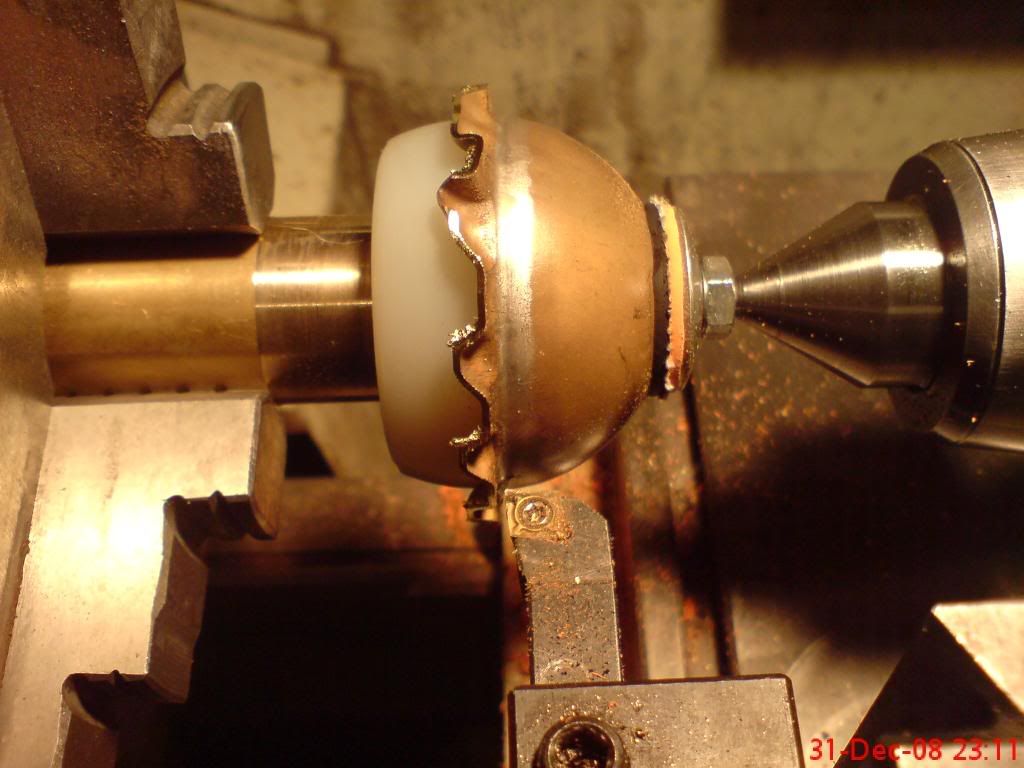

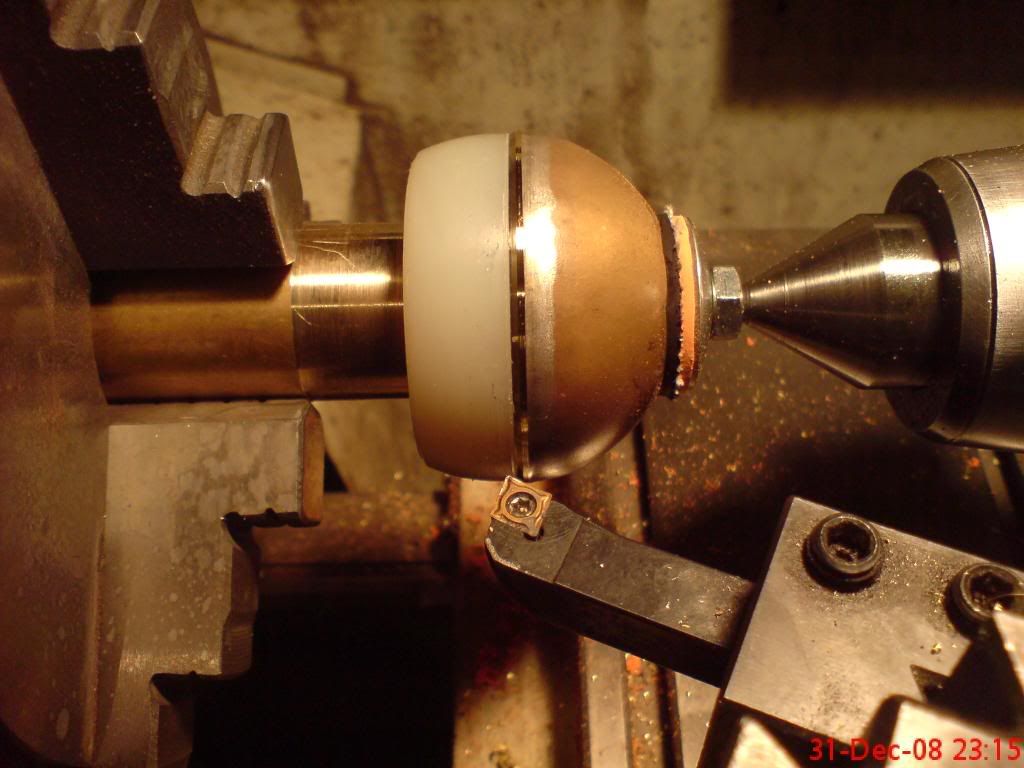

An arbour for holding the domes while trimming... Machining nylon is fun!!!! (M14x1.5 thread into the nylon and on the brass arbour.)

This was then threaded in the centre as well to take a M6x1.0 bolt from the front through the location hole in the dome, the dome could then be trimmed....

And finally... A little solder and a bout of emerying (is that a word?!)

I know it is not a ball.... It's a prototype for all my processes. I can now test all of my parts and mountings etc on this little fella

I had a lot of fun today, got out into the shop about 14:00 ish and planned and pottered about, apart from a gap for tea and topgear I spent the night in there, good music and machining... Who could ask for more? I was in there right upto and through into the new year!.... One of the best new years eve's I've ever had!

Comments etc welcome

Ralph.