I am a Vet and have to perform orthopedic surgery regularly.

Usually we can adapt implants made for people and use them on animals. But we sometimes have to provide special solutions with patients and make impants made out of Stainless steel or Titanium 6Al4V Eli.

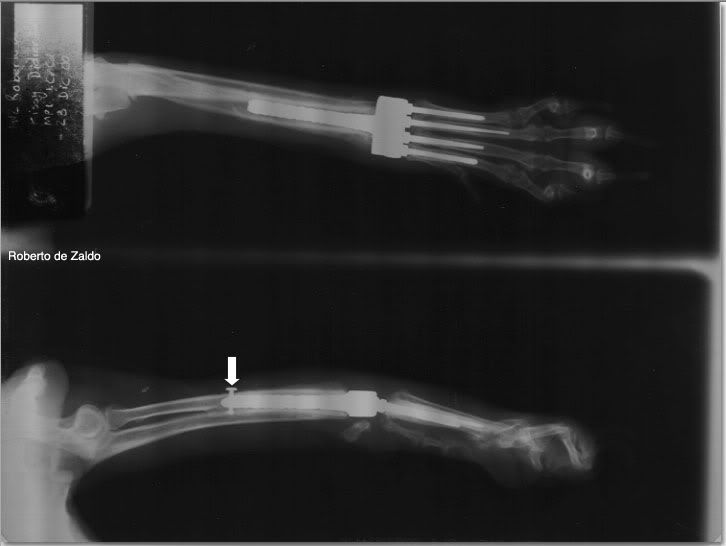

This are some pictures of the first wrist replacement made for a dog.

Machining titanium has a lot of little problems as we found out. It will self ignite sometimes and that is scary.

Turning was best done at high speed and drilling as slow as posible. In both cases using a lot of cutting fluid.

We like to use carbide tools , very sharp. Steady, and progresive cuts, with little load.

This one was one of our favorite patients. Called Kissy, had arthritis that deformed very much the limbs. ( antebraquiocarpal joint affected seriously)

I started by evaluating the patient, then designed the implant using Vector Works in a Mac and finally machined the individual parts using a little lathe mill drill from grizzly ( I use this for my hobbies and a little for my work) . Implant looks like a fork / hinge.

There is a radial component and a metacarpal component. Carpal bones were almost all removed.

This is the Xrays showing the implant in place.

Titanium is a very interesting metal to work with. It is like aluminum sometimes, but it can harden in a snap and break the tools very easy.

It is a lot better than Stainless steel when used for implants, because it is very biocompatible.