When I ordered an MT3 ER32 collet chuck from CTC I also got a 20mm plain shank one like this :-

The shank was removed with a cut off disk in an angle grinder, leaving this :-

Next the outer body was turned and drilled. Originally I intended to shrink fit it to the chuck, but it seemed a shame to

ruin the finish, so I uused JB Weld and two grub screws.

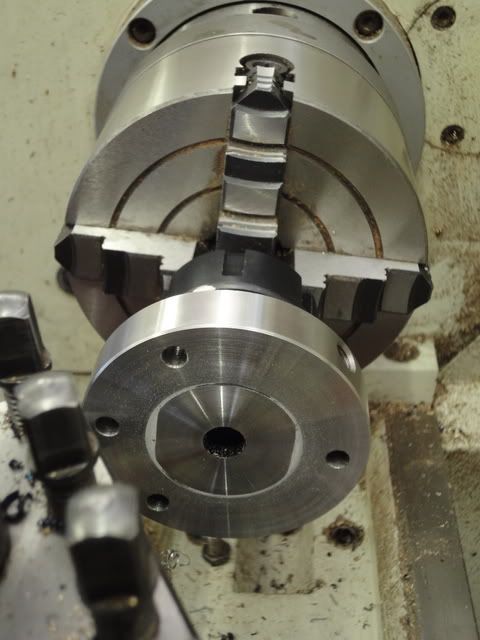

The cut off shank was mounted in the 4 jaw and trued up. Using a 20mm collet in the assembly, it was faced

and bored out to 16mm.

One of these :-

was turned into a 16mm spigot for the rotary table.

So, I can now mount chuck on the table,

or on the rotary table.

That will hold from 2mm to 20mm dia.

Thats all my modding for Today's post!

Ian