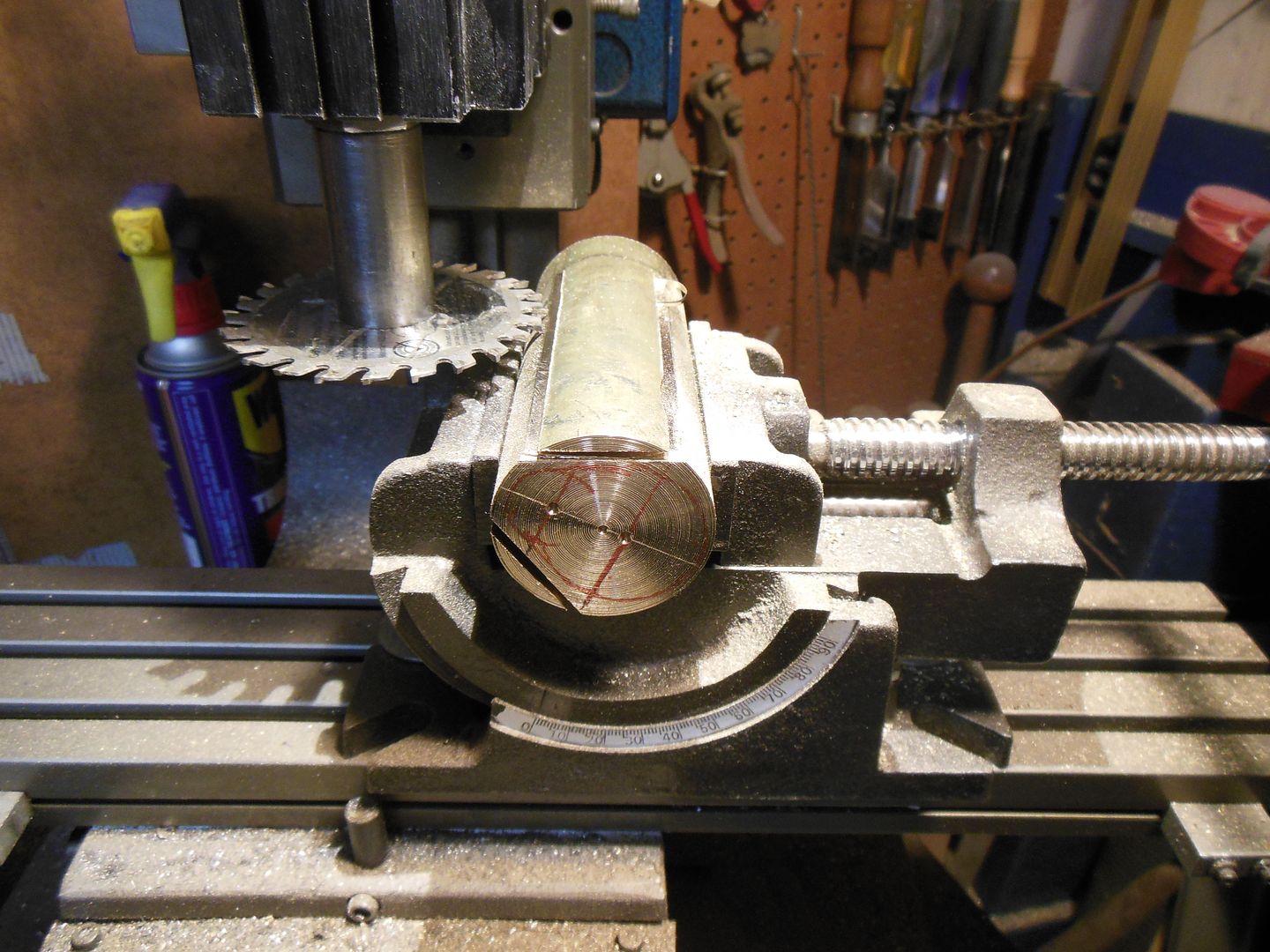

Well, started having at the nice bit of brass that came in last week.

Well hidden inside there are some rear-wheel hubs screaming to come out...

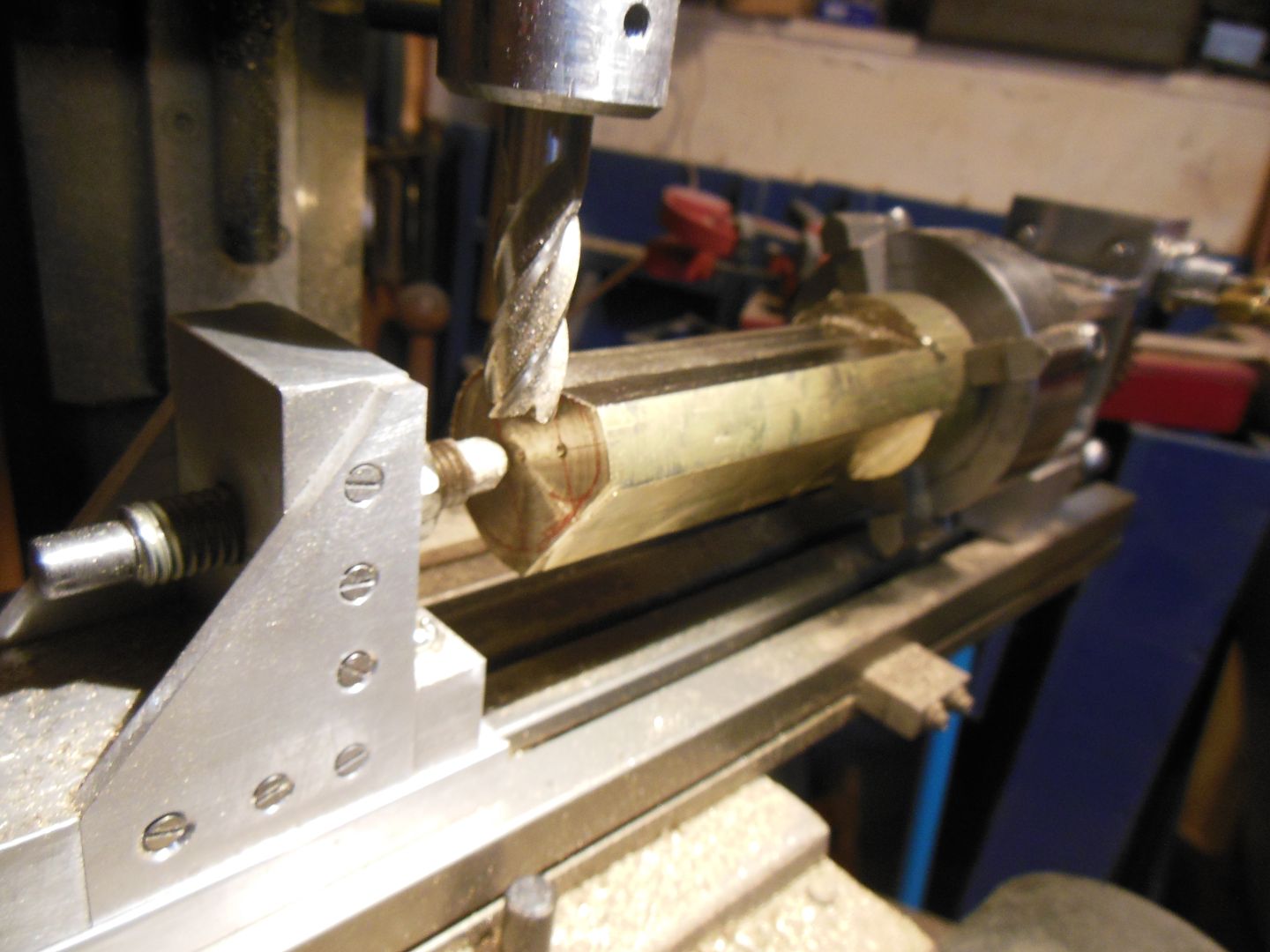

Set up in the mill to carve off some of the excess material

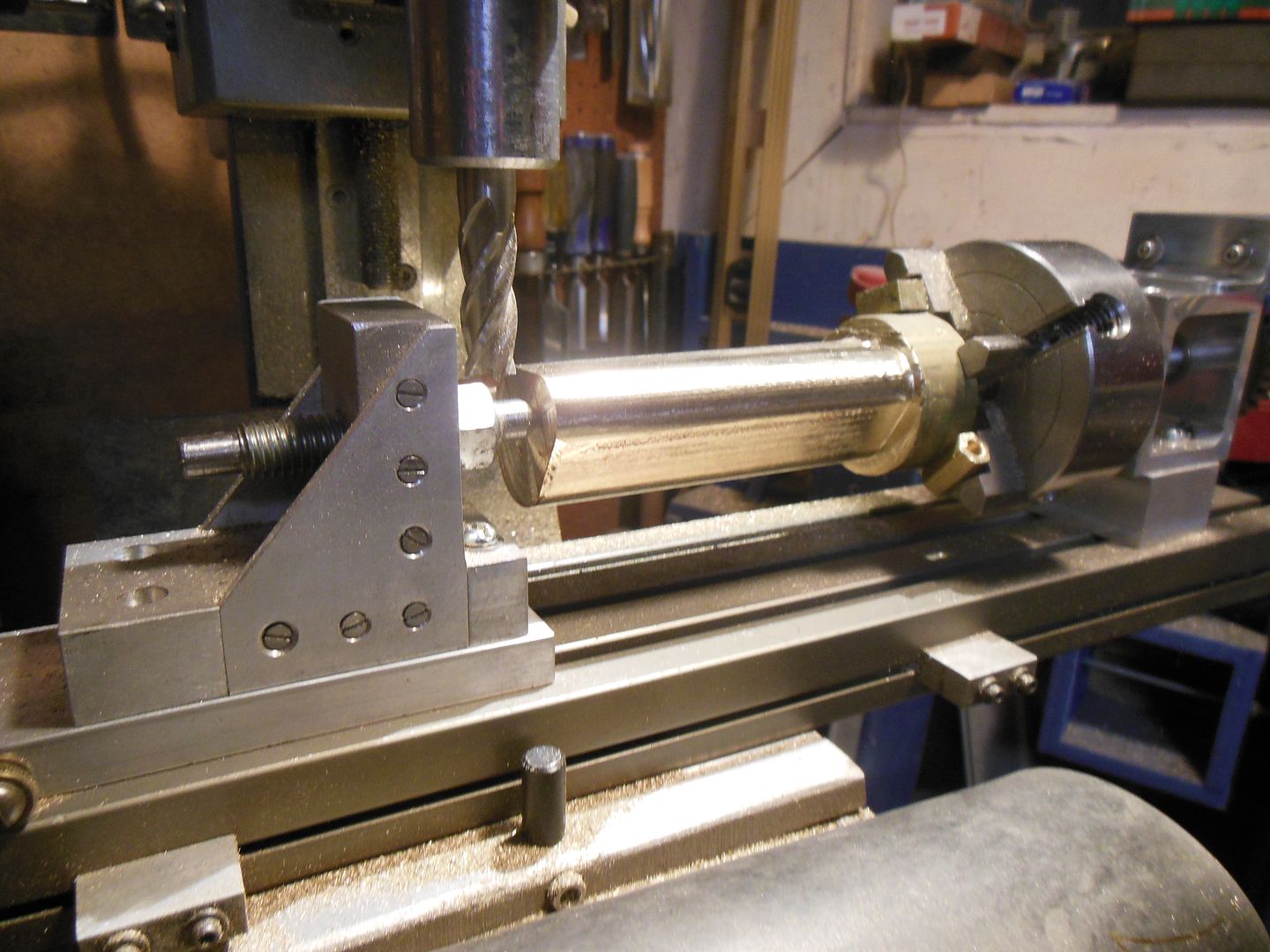

then mounted on the dividing head for a lot of passes to round it over, went with very small increments which leave me with next to

no clean up to do to remove the facets left by the indexing as they are really slight

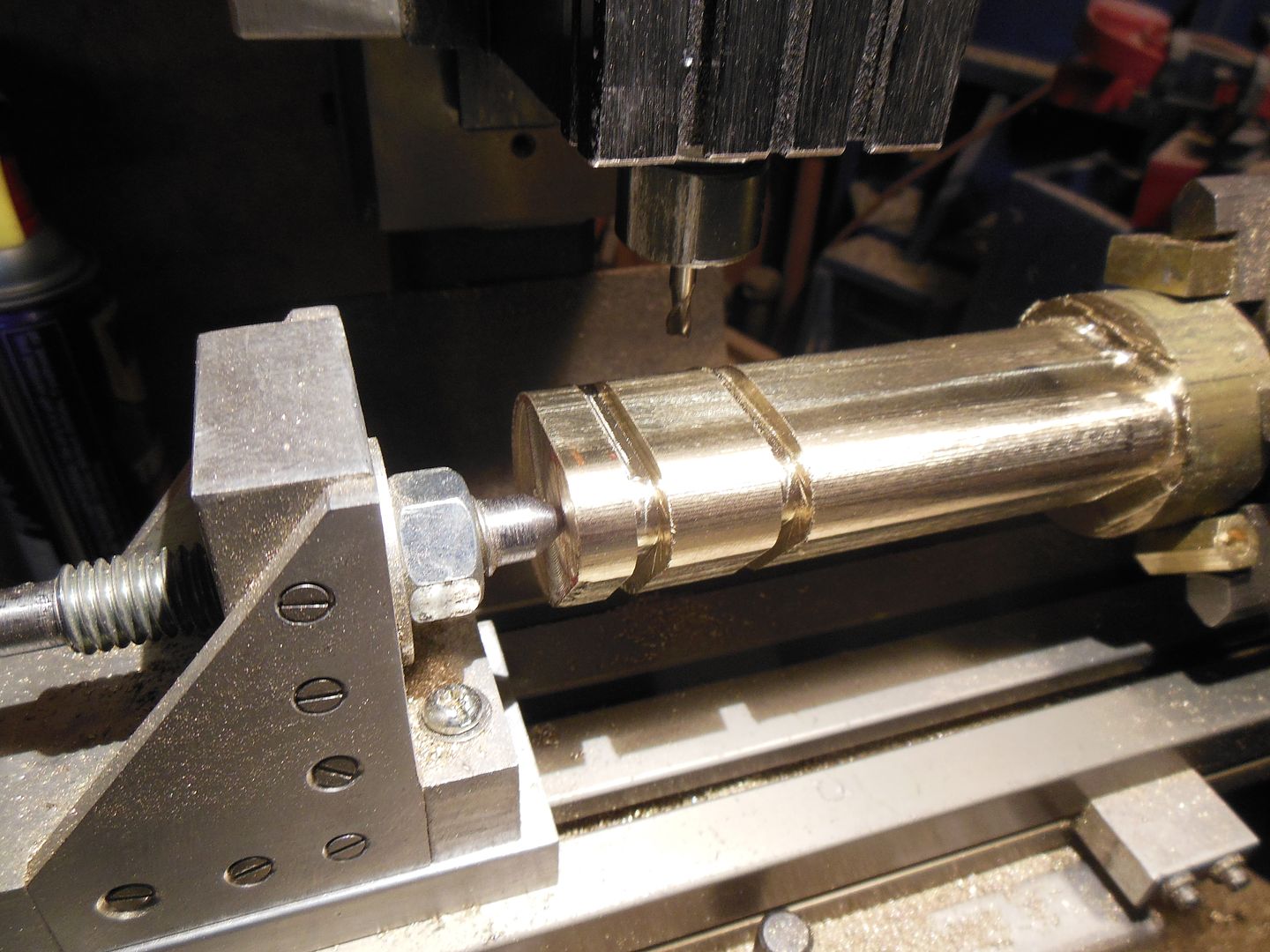

changed to the other centre to mill the smaller radius

once that was done, still on the same centres started to mill out the inside of the hub. So far once around with an end cutting mill,

next will go around each side of this slot with a 1/8' ball nose cutter, taking off another 1/16' on each side bringing the slot to size,

and giving me a nice little radius at the root.

Once that's done, remount once again on the other centres, and finish off the slot milling.

However, that's for tomorrow, it's time

Joe