Got the water gauge mostly done now (haven't acquired the glass yet :Lol:)

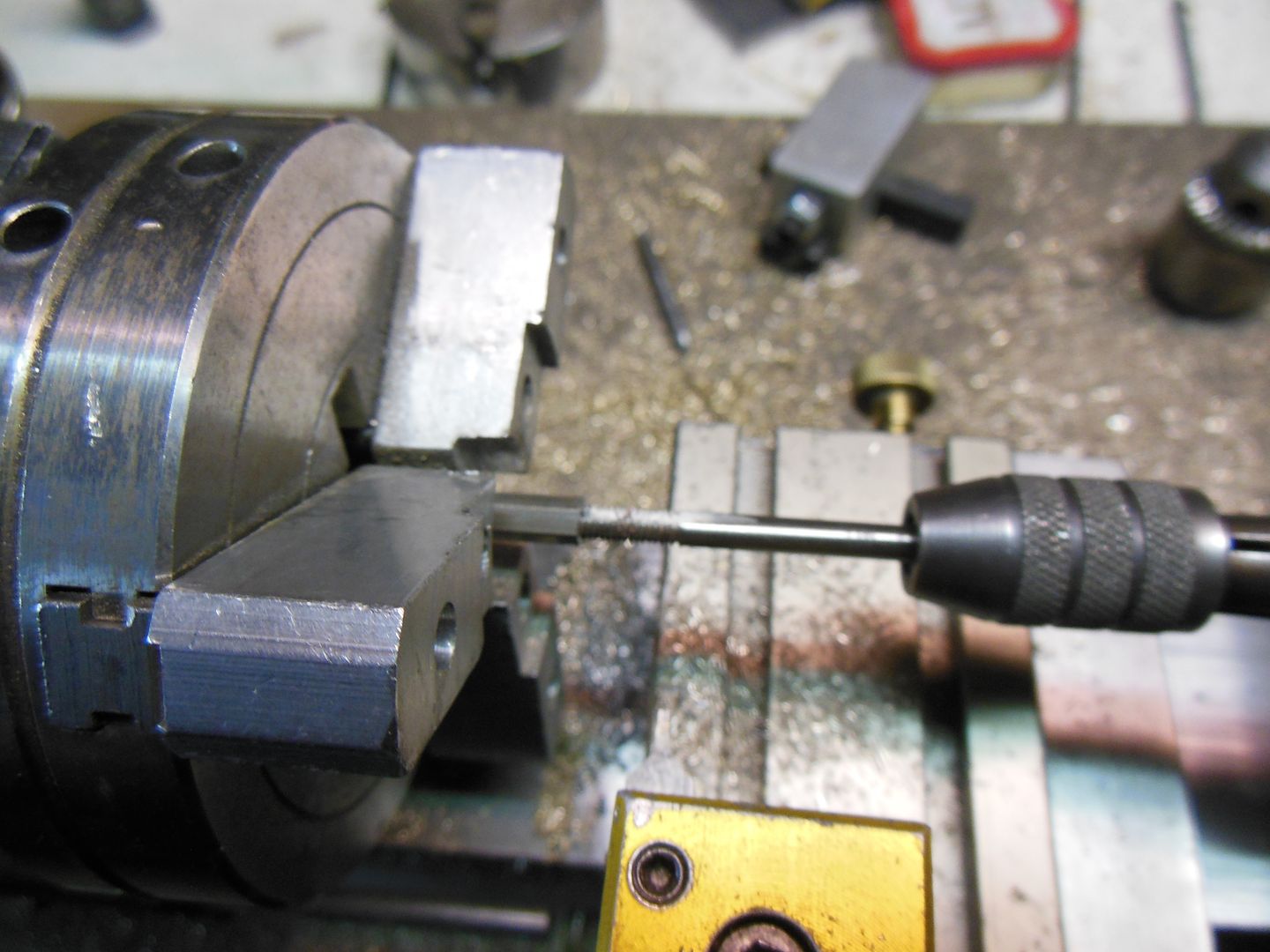

turned a bit of bronze, and threaded one end, then screwed that into a slug of ali in the 4jaw.

This was pretty unstable at the length sticking out, so ran a temporary centre out of the tailstock

and took really light cuts. Used a ball end mill to form the transition from the shaft to the base of the part

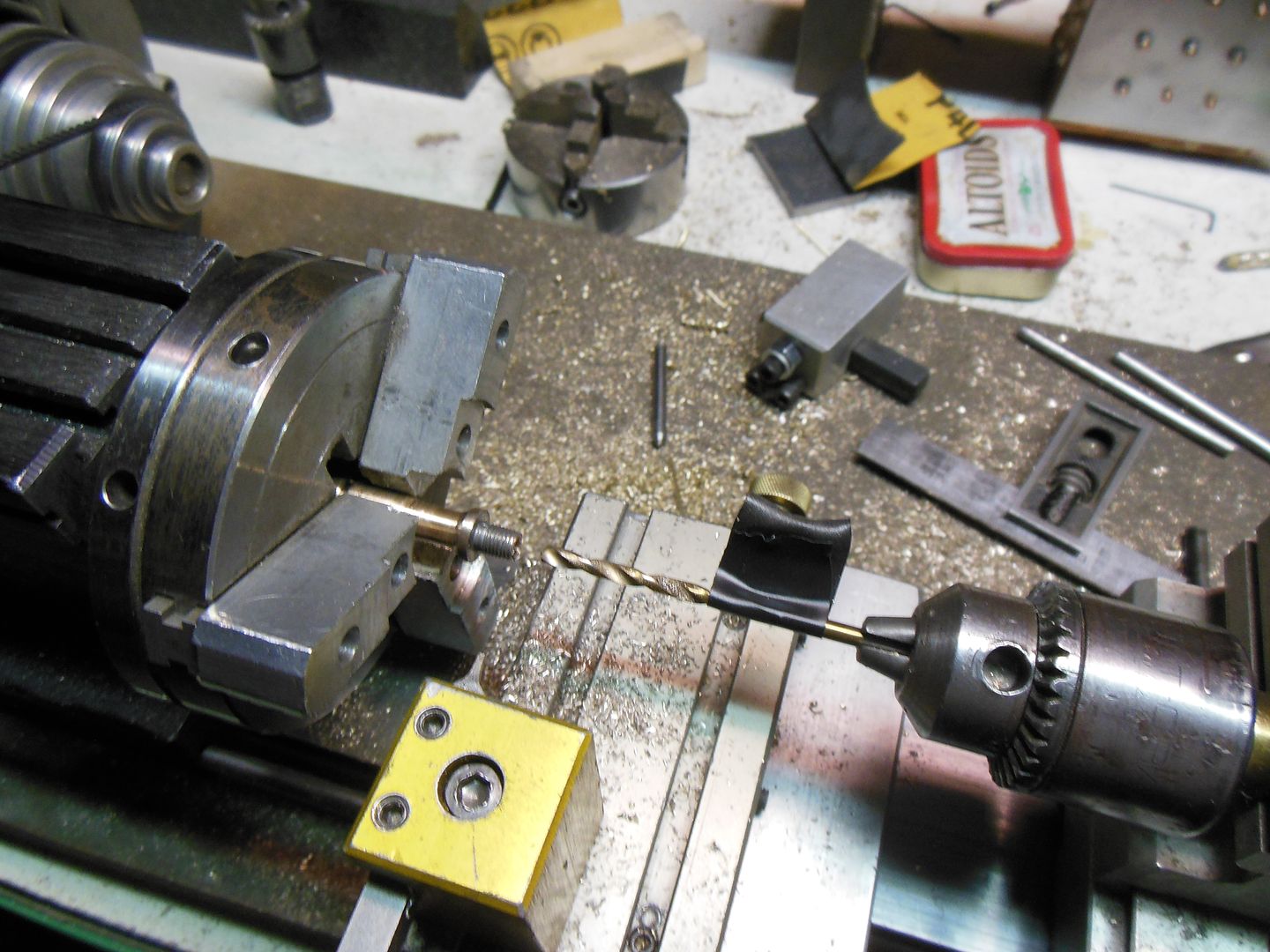

once all the turning was done, chucked it up in the Taig to drill out the steam passage (the second time around. First time,

drilled it the same time I threaded the end, and it sheared off when I tried to do the turning...not enough meat left for the

stresses imparted

note the high-tech depth gauge on the drill bit. Tolerance of +/- 1/8" on this hole....

these parts have tapped or threaded spigots coming off them, this was straightforward turning drilling and threading with a die,

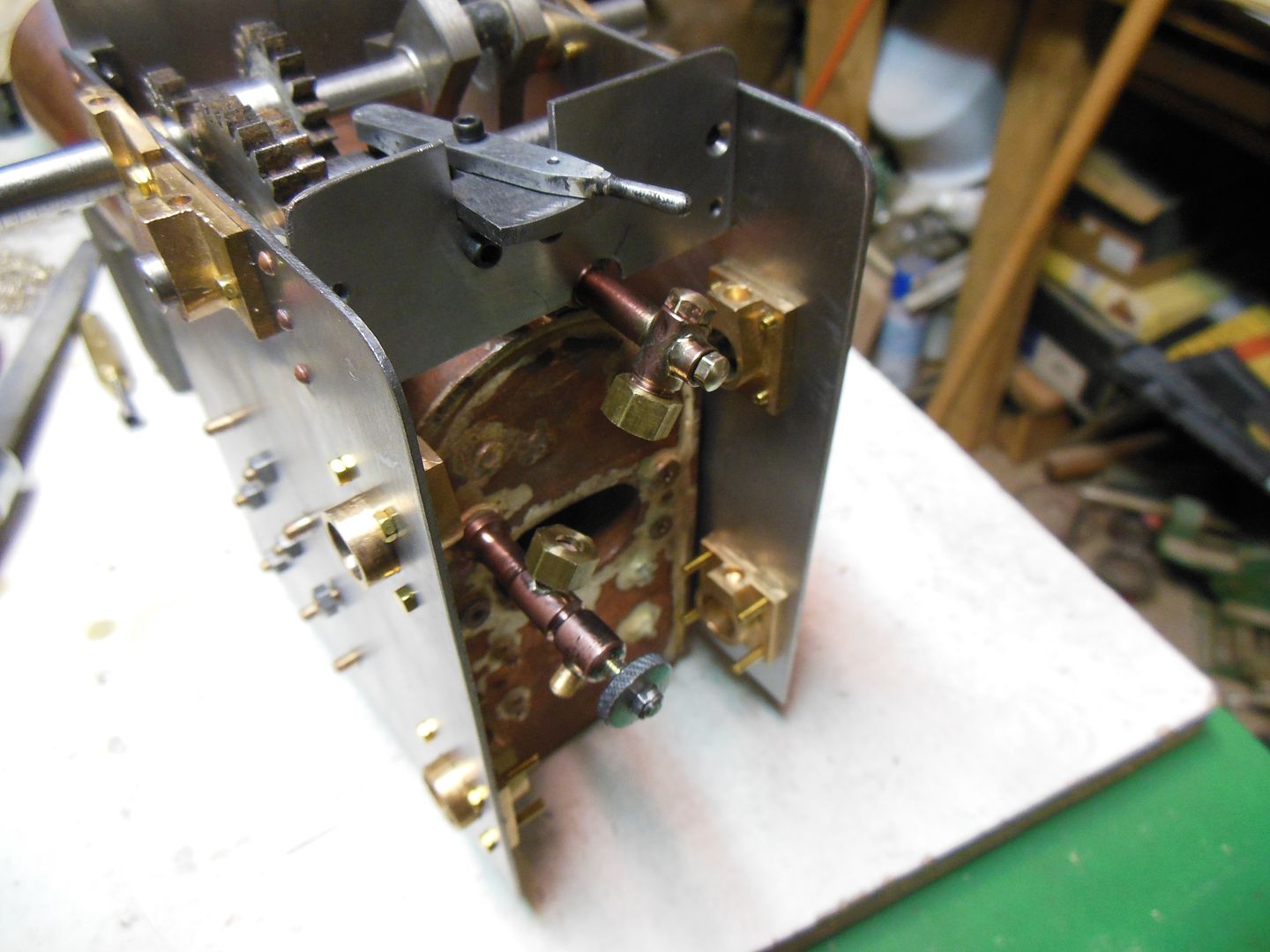

and then assembled with some flux and silver-soldered

and then into the pickle, and do it all again for the upper end.

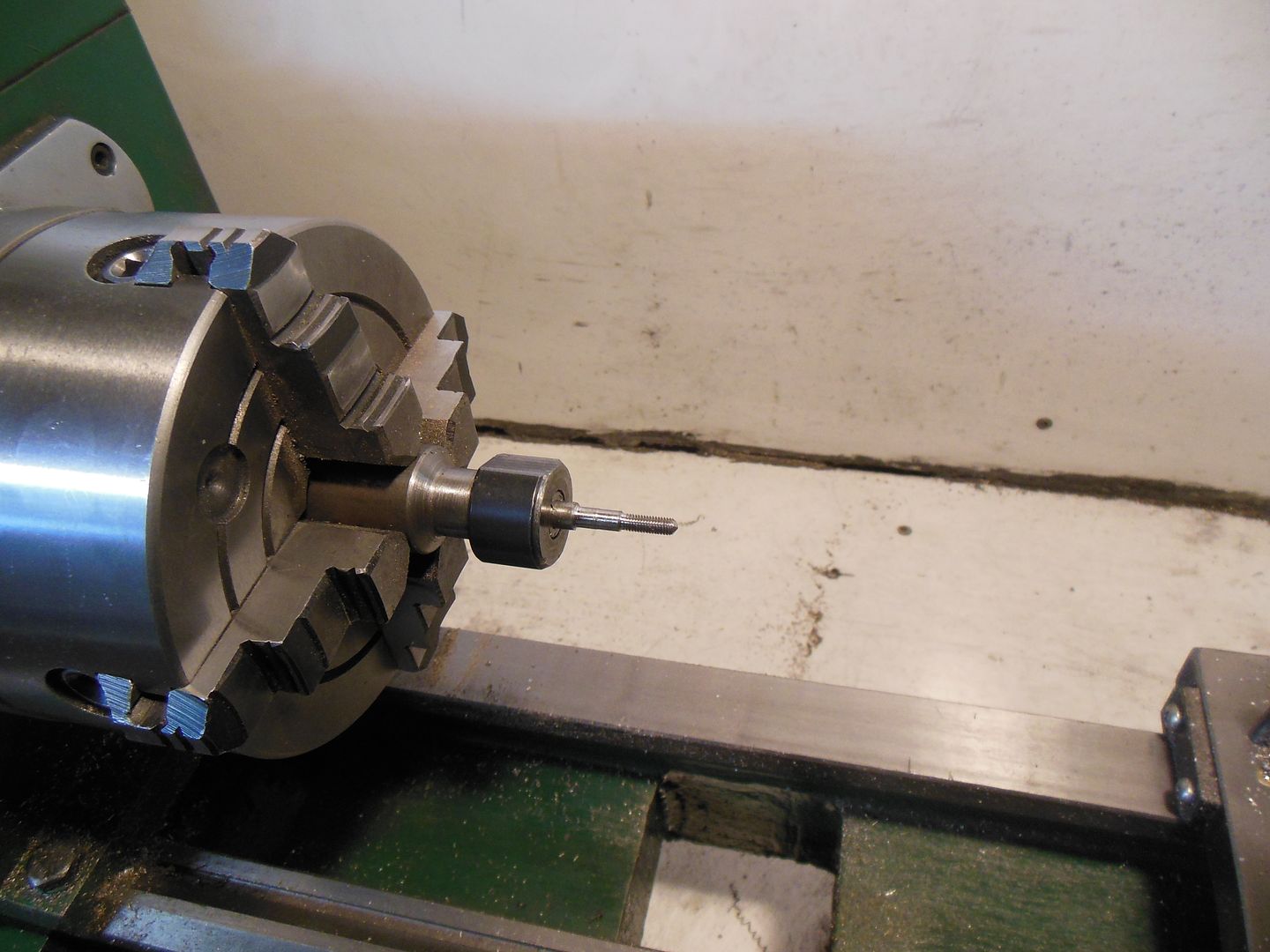

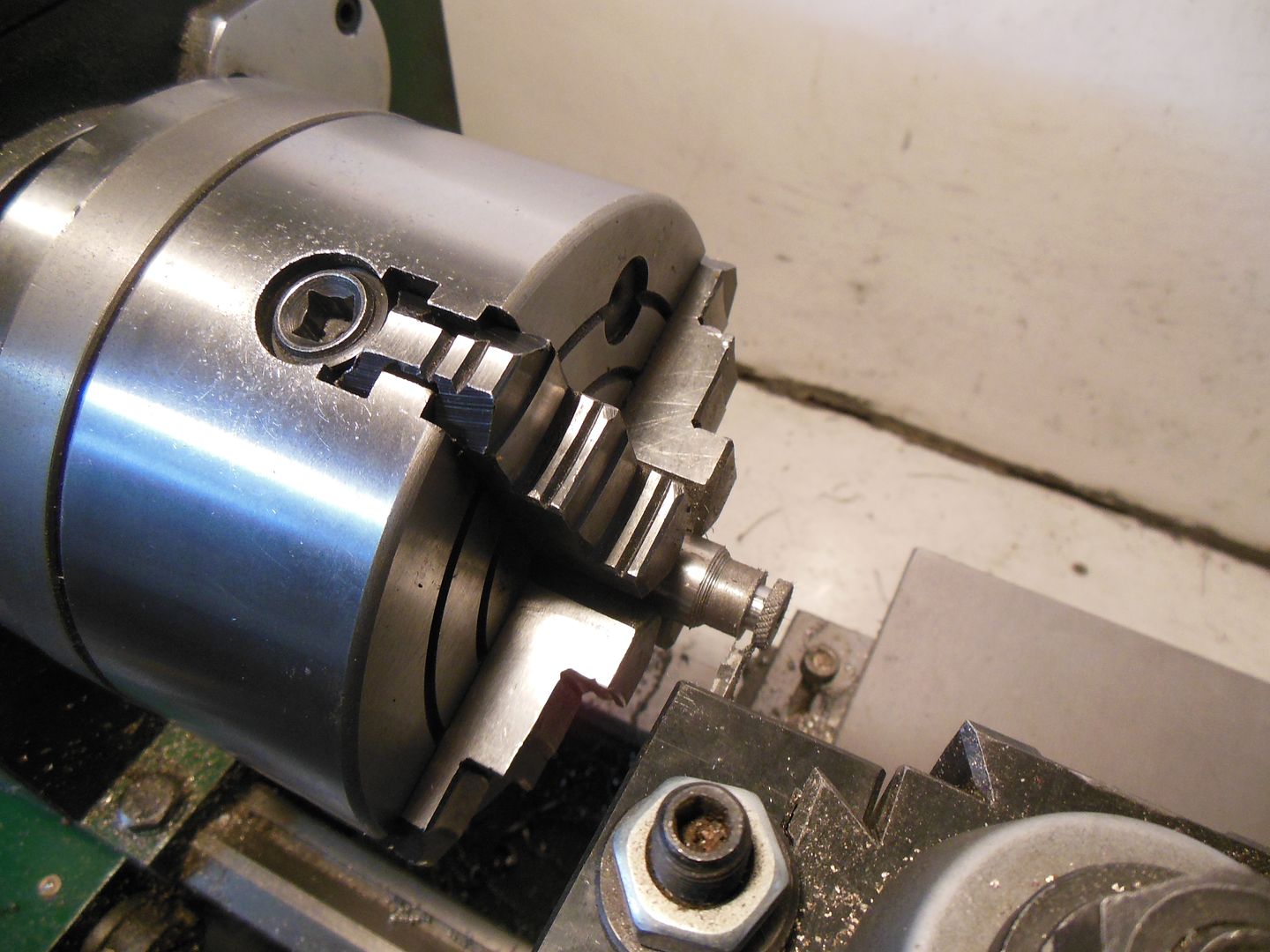

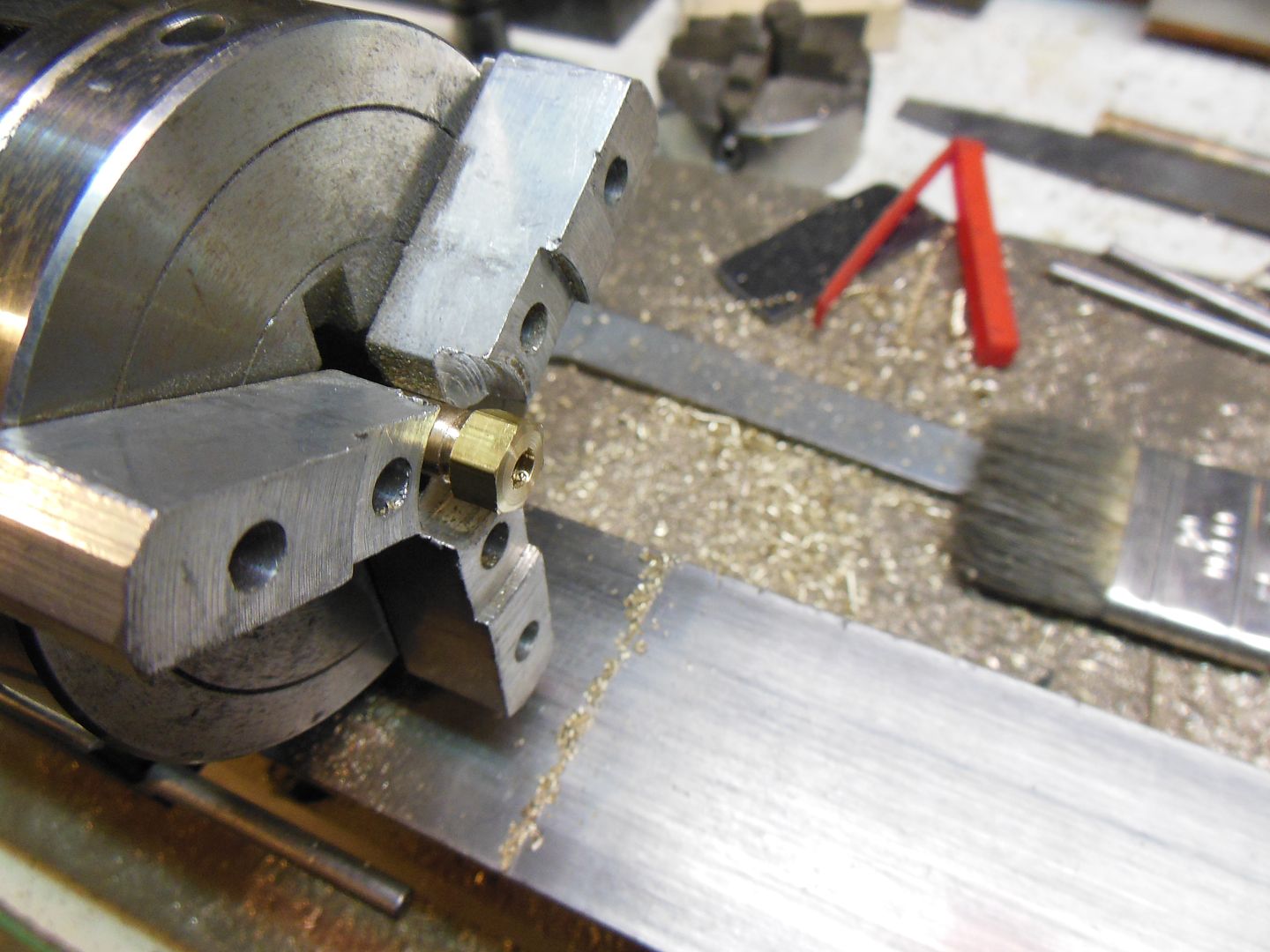

The lower fitting has a blow-down valve so turned and threaded a bit of stainless (started out life as a 1/4"bolt) as a valve spindle. The big lathe can't handle stock this small in it's 4 jaw, so for a previous project I had turned a spindle that mimics the spindle nose of my Taig lathe so I can use the collets that fit that lathe in it's big brother

Turned, drilled, tapped, knurled, and parted off a bit of 12L14 for a handwheel

Made a really small locknut for the handwheel in the Taig

finally, made up the nuts that will secure the glass tubing

and after some clean-up with a wire wheel in the dremel, put all together, and put it in place. will work better once the tubing is there!

and that's it for now!

cheers, Joe