Overnight, I had a chance to reflect on things and progress so far. I decided that because I had a second identical drawer unit in the shed, I would add it as well!

You can see I also added a couple of extra braces to the bottom shelf.

For this pic, I jammed the lid of the toolbox in the back above the coolant tank and it looks like I could add a small shelf for odd stuff but it will have a hose running through it. You can see I have fixed the cross member that was in the road.

I don't know if I will put this in here yet, but certainly food for thought!

The bottom drawer unit is just hanging down from the handle mounts.

and a few more shots to show you the detail

So pulling the second drawer unit out of my shelf has opened up a bit of a gap in the shed

Hmm, I gotta fix that wonky shelf. I've got some material here I bought for the job.

So here is the plan for a future project. The lathe destroyed a drawer in the cabinet on the way down and I bought a replacement to make good the damage.

I worked out that I should be able to cut the bottom drawer away and the remaining 4 drawers will slide into the available space. This will look nice and neat as I have 2 of these drawer units in the shed already.

I decided that there was some spare space beside the coolant tank and I had a set of surplus 550mm long x 100kg drawer runners here that were itching to be used on something and they were the perfect length so I set about making up a frame to hold them from 5mm x 50mm flat bar.

** Post 4

So the frame was pretty much done and ready for paint aside from a few finishing bits. It is pretty cold here and not good paint drying weather so I decided to paint it Friday evening and fiddle with other stuff for a day while the paint dried.

Chris down the road suggested I add some lifting points to the frame and I thought this was a really good idea but his idea of adding some eye bolts was not going to work, so I came up with this idea and added two foldaway lifting tabs secured with M12 bolts at diagonally opposite corners.

The other thing I needed to do was to turn up some mounting pins for the external legs

Because of the tight clearances, the heads had to be less than 3mm thick. I started with 25mm steel and turned it down to 19mm. By using the cariage stop I made and a piece of rod held in the tailstock, I ended up keeping the dimensions identical which I was pleased with. I just have to work out where to drill the holes for the leg pivot points.

It took a while to drill the mounting holes for the casters and I had decided to buy some fancy 125 kg casters instead of using some unknown capacity wheels that came on the grey drawer units that I replced with home made adjustable feet. Of course the brake lever on the new casters hit the stand legs so I had to make sure the wheel mounts were set slightly off centre to get clearance. I am using 50mm x 75mm x 6mm angle iron for this.

The upright needed notching which was a good chance for me to play with my new plasma cutter

Nothing like a live job for the very first cut and you can see I got a bit carried away. I have never used one of these suckers before but I like it a lot!

So after working out the height required for the leg uprights, I drilled an 11 mm hole in the top of each one and used the plasma to trim up some short pieces of angle iron to form a tab. I drilled the hole through the tab back on the mill so I could use the existing hole as a guide.

Looks like this is going to work out OK, I just need to drill the cross holes in the pins

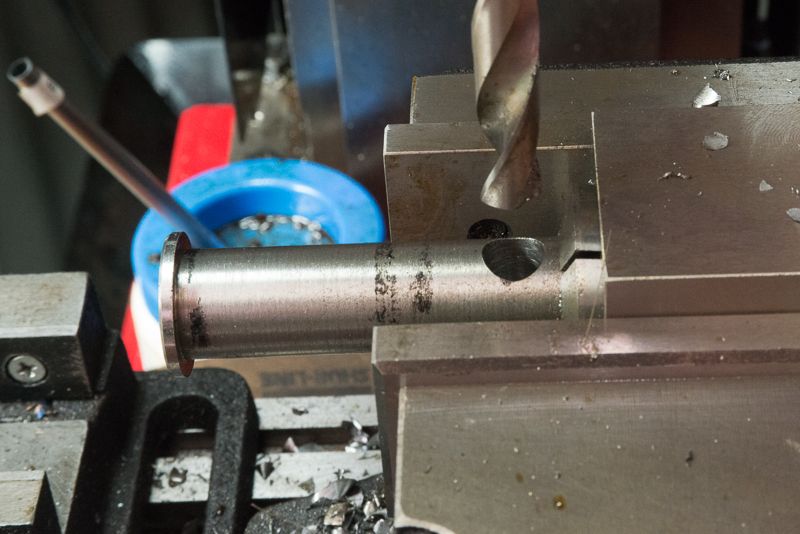

So back to the mill and I grabbed my collet blaock and the collet stop I had bought from Little Machine Shop. I used an edge finder to find the edge of the pin and moved over to centre the part under the drill. I still don't have a spotting drill, so I used a centre drill to start the hole.

and followed through with an 11mm drill.

This workflow worked really well as I drilled the 4 pins with one setup and everything was identical. So now the hinge for the top of the legs is complete

I decided I would not bother with using a hand winch to pull the stand up on its wheels as a lever would work just as well. So I welded on a bit of 25mm SHS to hold one.

The lever for now is some 16mm Hex bar I had here. It really needs to be replaced with something that is a tighter fit in the SHS but I thought a 25mm dia lever turned down to fit the SHS would be a bit of overkill!

So the idea is to bolt the wheel assembly on, insert the lever into the leg.

And stomp on it!

and secure the leg with a 12 bolt each side down the bottom.

It will be pretty cool if this actually works once the lathe goes on!

So now time to look at making provision for a coolant drain. Chris had also suggested to press a dimple in the drip tray using two sockets. I had to do this in situ so thought I would see if I could just use a bolt through a 12mm hole to achieve the same result.

This actually worked really well.

I had seen a steel 3/4" hose joiner with a barb on each end and I thought if I was to part it in the centre, it would make a good tail.

Chris said he welded them on. I was a bit worried about this as it was going to have to be an overhead weld in situ as I did not expect the drip tray to come away from the lathe after I Sikaflexed it on the first time. Of course as I expected I blew a hole through which was still OK after a bit of a repair but at the last minute I tried to patch a pin hole and totally stuffed it! So you are just going to have to wait until I tidy it up to see a photo.

Well, ready to comission this thing. You can see I used some checker palte to make it go faster. The front cover plate in front of the drawer unit is held on with stainless domed screws but the bottom shelf is pop riveted on.

It looks good and I got the mounting hole dimensions spot on.

Still have to sort out the drawer unit yet!

I bought a right angle drill head today so I can drill a couple of holes at the front to finish off mounting the drawer runners. I knew I would have problems with this when I built it but as I did not really know how it was all going to mount up at the time, I decided to just press on as it was hard enough getting everything into position and tacked up on my own.

Anyway, I will update this as I finish it off over the next week or so. I would like to make the drawer out of the checkerplate but I can't bend it myself so I might just get somebody to make it for me yet.