Hi

I finally received the speed control module this morning.

I quickly connected it up to test and it worked ok so time to wire it all up and stuff it in the box.

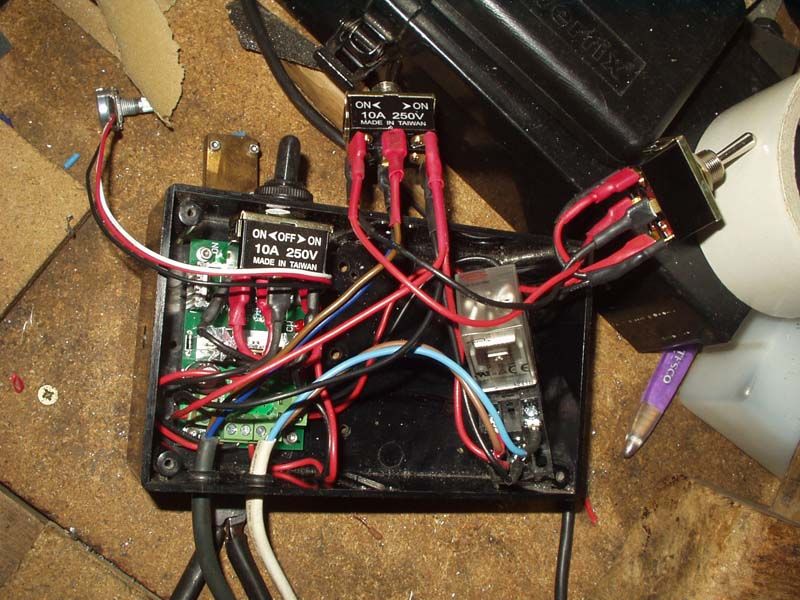

this is all the bits wired up but flapping about.

this is everything in the box, the l/h switch is left and right drive under speed control, the r/h switch is left and right drive under full power for rapid traverse and the centre switch selects between them. the speed control knob is on the l/h side.

and here its all buttoned up and ready to go.

If anyone is wondering, the relay is to completely disconnect the control module input and output when the rapid traverse is being used,I didn't know what would happen if I fed power into the output terminals of the module, knowing my luck I'd let all the magic smoke out.

The advantage of using this cordless drill is it has a two speed gearbox with a large space between gears so I have a neutral position for hand winding.

I'll try to do a video tomorrow to show it working.

thanks for looking.

Roy.