Hi all , I am hoping that someone can help with a problem of a chuck that is stuck on my lathe spindle. I am on the finishing jobs of my rebuilt Harrison L5 and had screwed the chuck on with very light hand pressure only after cleaning both spindle and chuck then applying light oil. I have not even turned anything in the lathe but when I have come to remove the chuck its stuck fast. Proper stuck fast too.

So far I have tried .

large hex bar in the chuck and big spanner on it, tapping the spanner to shock it and jerking spanner with the gear train locked so the spindle can not rotate.

The usual realeasing oils etc, left over night and also repeated after heat applied

Removing the chuck from the backplate , incerting 3 bolts through backplate holes and levering with 3 feet long 1 inch bar , hitting said bar to shock

Heating the backplate up with propane torch and trying to shift while hot , then when cooled again, tapping all around trying to break seal

Replacing chuck and chucking large hex bar then trying to loosen with large socket and windy gun. ( only thought of this after the other attempts )

The force used so far and the hits have gradually reached the point where something is likely to break if any more force used so looking for ideas. It would seem totally impossible that it has become stuck this tight. I know 100% the threads are clean, there is film of light oil and the chuck has not been tightened other than by light hand pressure. I am assuming the rear face is seated against the spindle shoulder and the 'lock' is between this and the threads, will this be the case ? I think it must be as this chuck has been on and off many times before and I know the register is clean and oiled as are the threads.

Here are some photos of what I am dealing with.

This is a samller bore Harrison spindle of the exact same design showing the thread, register and shoulder, then the chrome cover, note the shoulder sticks out the chrome cover a small amount. The actual one on the lathe is clean and spottless and oiled.

This is the same design backplate that is stuck on my spindle, showing the register and rear face that is butted tight to the shoulder on the spindle.

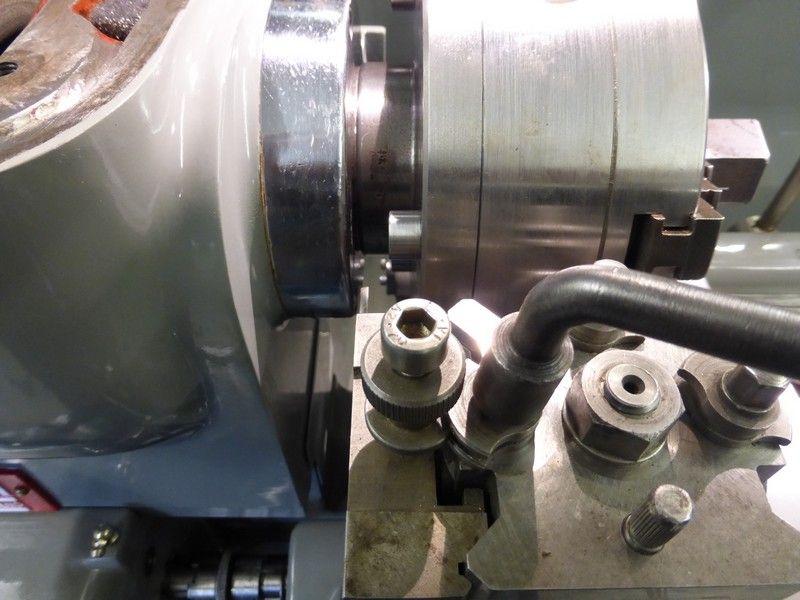

This is the stuck backplate with the bolts through it , that the large bar was acting against both jerking and hitting with the gear train locked stopping the spindle rotating, I have gone to maximum force with this , it would have shifted a truck wheel nut in my opinion.

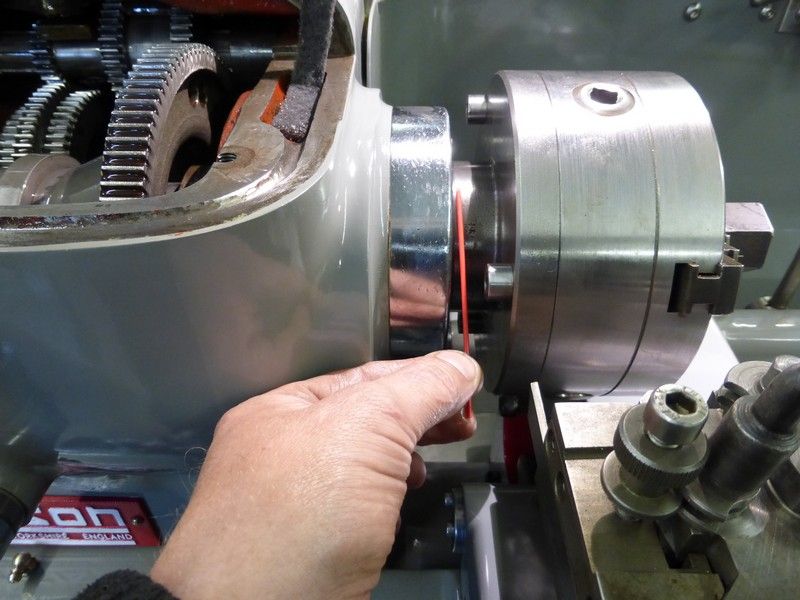

This is a shot to show the spindle shoulder just visible coming out the chrome cover, the backplate is mated up to this. I have a parting tool in the tool holder to show roughly what a plan might be ?

The red small tube is pointing to the spot that I could with a slim parting tool slice into the backplate just shy of where it mates to the spindle shoulder and releave the tension or compression causing the locking.

So really what do peolle think is causing the thing to be seized, what I think some sort of hydraulic type lock or taper type lock between the backplate mating to the spindle shoulder or could it be the threads ? they are clean and oiled. I would really like to svae tha backplate as a hard job to find them for decent price and do not want to have to make another one, I do not want to damage the lathe in any way.

All Myself and a friend can come up with is to maybe drill very small holes in the backplate so releasing fluid could be directly introduced into the threaded area ( if that is what the problem will be) Or to make a special parting tool so it could part away the very end section of the backplate nearest to the spindle shoulder yet miss the spindle by a thou or two, I could also make the tool so it could not go in too deep and mark the spindle as I have a smaller spare backplate with the exact same register to measure.

Any help most appreciated

Cheers Mick