well.... i have completed the install. the z axis was by far the most complicated. The slide bar i installed worked, its runout is about .005 overall length both ways, the bushing i put into the quill plate holds the tolerance for what this set up can handle, granted i have not used it allot yet, but i have run it up and down at least 40 times, also milled a slot to depth and it showed dead on, saying that it may gradually loose tolerance.

Here is the bracket from the slide rod.

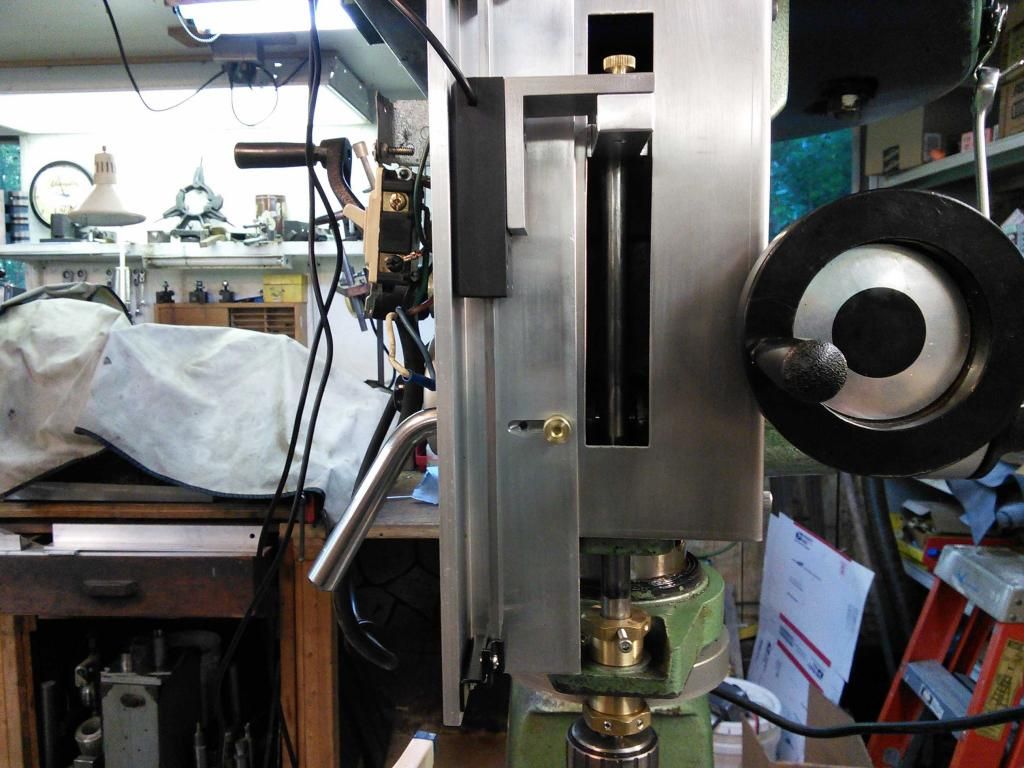

Here it is installed.

All i have to do now is make a cover plate for it.

It from the picture dont look square but it is.

If anyone is going to do this install make sure all your fixture holes can be tweaked, slots and wide hole clearance are a must, all fasteners can have washers which will take up the width. My Bushing arrangement worked, the key was the straight piece of instrumentation tubing i used, a straight piece of drill rod will do the same, there is slight play but the closer it gets to the bushing it closes in. My tolerances on the rod are less than .005 on both directions.

I will use this set up for a while and report what find, all in all i am happy with it.

Anthony.