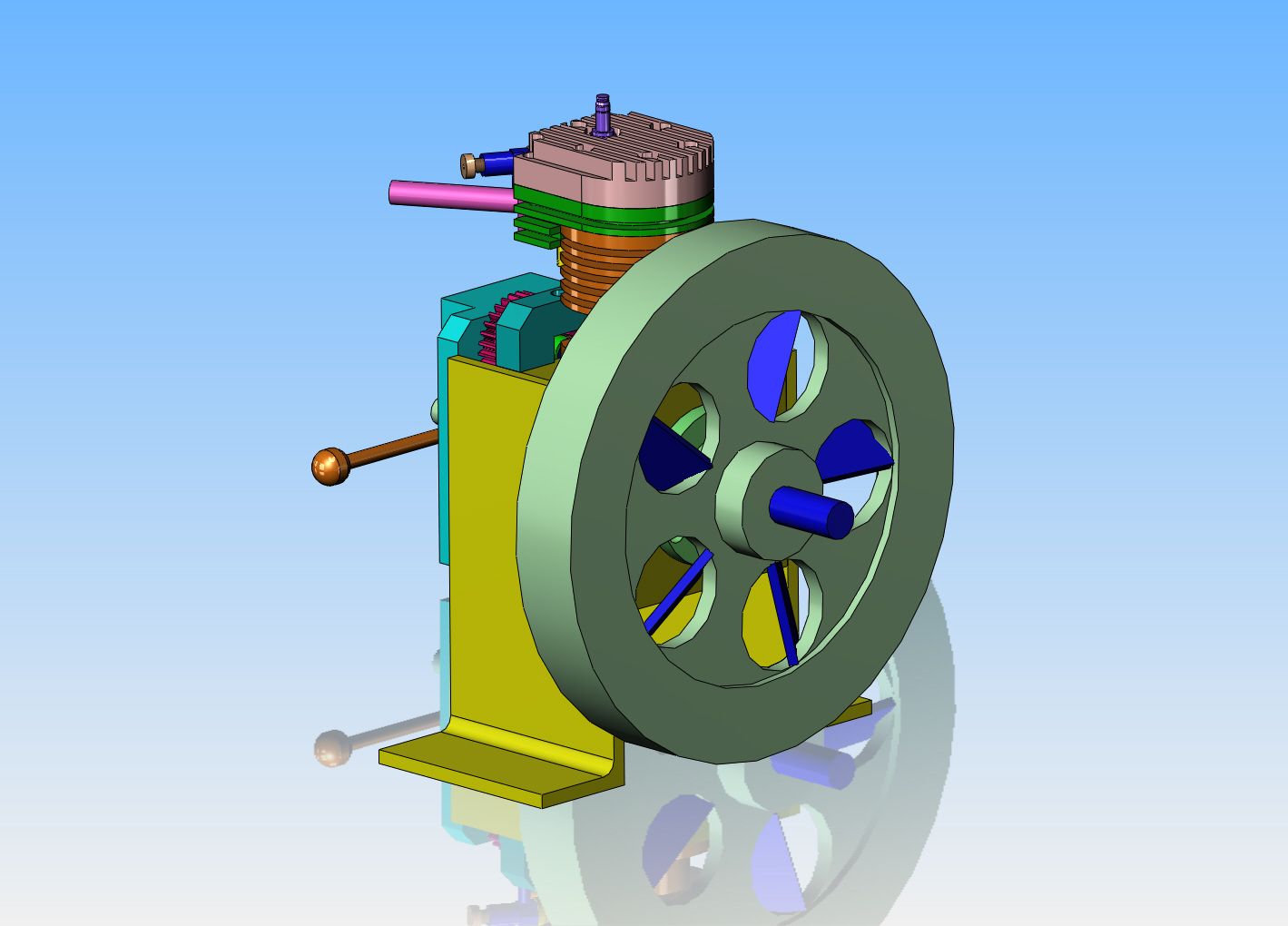

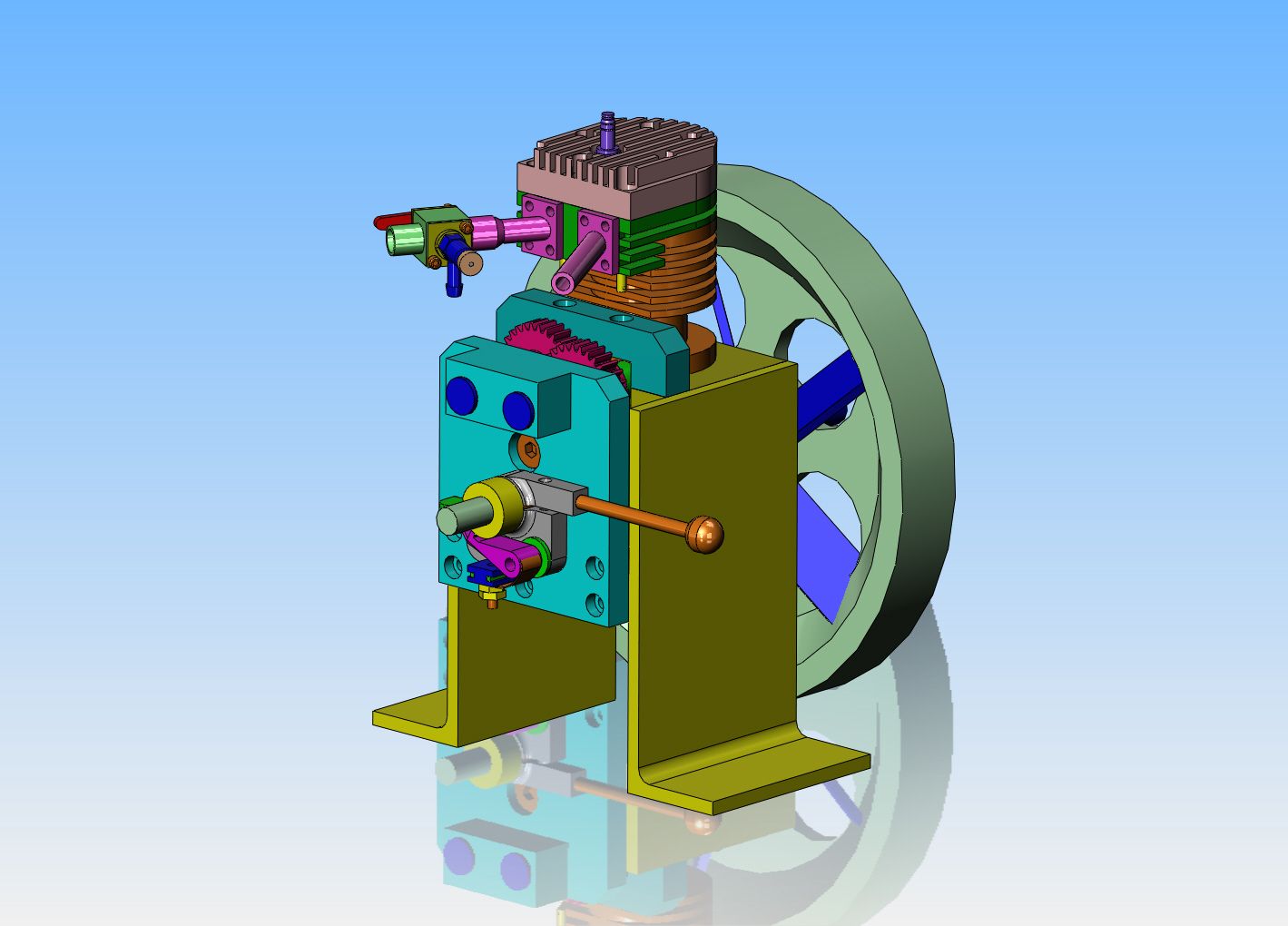

This is the point at which things begin to get a bit----goofy? The engine needs a flywheel. Past experience has proven to me beyond a doubt that the larger diameter a flywheel is, the better the engine will run and idle. Throttle response won't be as quick, because that's a lot of mass to move, but if fast throttle response isn't vitally important, then a large diameter flywheel is the way to go.

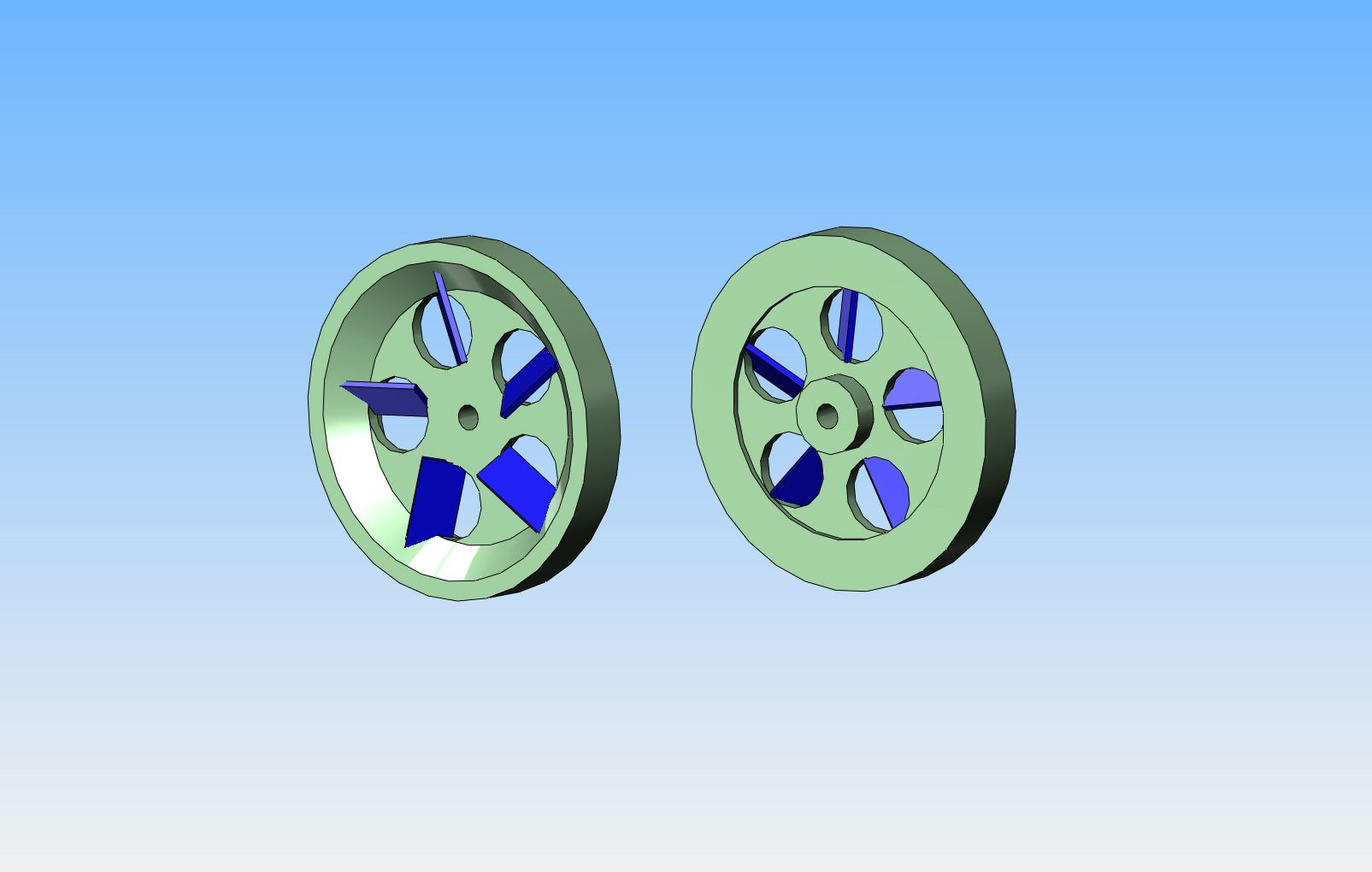

The flywheel shown is 7" diameter, which is about 1" too much in my opinion, to keep the proportions reasonable.----So----Why make the flywheel so big?--Because a second factor I have proven to myself, is that without some kind of airflow over the fins, the engine will rapidly overheat. All you guys who build these small engines with a propeller, like for instance the Nemett series by Malcolm Stride will know how much the air from the prop will cool the engines. I don't like propellers.---Having once, in my jaded past, stuck a finger into a (thankfully small) propeller on a model gas airplane, I HATE propellers. So---What to do?--I need a flywheel anyways, it has to be made from steel (can't afford brass) and I can weld steel. ----By making the flywheel 1" larger in diameter, and drilling 5 holes through the web, I can then make up 5 blades of .125" thick steel and weld them into the holes at a 45 degree angle. This will create lots of air movement, yet the flywheel will have a smooth outer rim in case some poor fool like me inadvertantly touches it. It will work. In fact, I think it will work very well. The only downside is that it makes the engine look "goofy".